We are going to exhibit at one of the largest world exhibition / IFAT 2022 Munich, Germany

We are going to exhibit at IFAT, World’s Leading Trade Fair for Environmental Technologies. This is a joint exhibition with ETIA, a part of VOW.

| Exhibition name | IFAT2022 |

| Period | May 30ーJune 3, 2022 |

| Place | Munich, Germany |

| Booth | Hall:A4 Booth:NO.421/520 |

| Exhibition product | |

| Biogreen / A electric heating type pyrolyzer carbonizing, gasifying, oil producing equipment, Internationally patented technology | |

| Website | https://ifat.de/en/ |

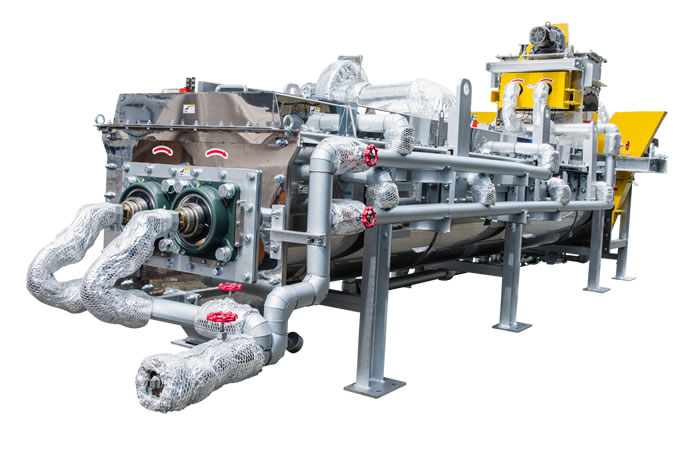

Dryer having 11 patents in 8 countries which is for drying sticky and adhesive materials such as sludge, slurry, etc. About KENKI DRYER’s works.

Actual installation examples of KENKI DRYER which is a dryer for sticky and adhesive material containing high moisture, sludge waste, sully etc. will be exhibited.

KENKI DRYER which is a dryer for waste sludge and slurry has 11 patents in 8 countries and can easily dry sticky and adhesive materials containing high moisture contents that no other product can deal with by its continuous low temperature drying function and the dried materials can be recycled.

Drying heat efficiency is very high and amount of saturated heat used as heat source can be kept low.

Continuous low temperature drying equipment KENKI DRYER.

KENKI DRYER which is a continuous low temperature dryer has 8 patents in 11 countries and can dry sticky and adhesive materials containing high moisture contents that no other product can deal with by low cost.

It consumes low energy because of its high drying heat efficiency, and decarbonation with no greenhouse gases emission is possible by using surplus steam from the factory.

Machine cost can be covered by reduced cost of waste disposal for 2 to 3 years, dried materials can be recycled because of its low temperature drying method and machine maintenance is easy because of less parts consumption.

It can be run for 24 hours without operators.

We have a lot of experience and results.

| Please consider KENKI DRYER for drying of sticky materials, adhesive materials and materials in liquid state that no other dryer can deal with. |

| Initial, running and maintenance costs are low because of its simple structure based on internationally patented technology. |

| For sludge drying, costs of our dryers are estimated to be retrieved within 2, 3 years by reducing industrial waste disposal cost. |

| For raw material slurry drying, laborious works of manual operation will be decreased significantly by replacing box shaped compartment tray dryer with our dryer |

| In case of organic wastes drying, the waste can be recycled as fuel, fertilizer, soil conditioner and feedstuff after being dried. |

| Company site No more trouble. Conveyor, Industrial environmental equipment and apparatus | http://kenki-corporation.com |

| Pyrolyzer Biogreen A pyrolyser with internationally patented technology which use no fire | http://www.biogreen-energy.com |

You must be logged in to post a comment.