Green tea lees drying, Low temperature drying for upcycling of green tea lees with high moisture content / KENKI DRYER / Green tea lees dryer, Upcycling dryer

ENKI DRYER: The Ideal Solution for Drying Green Tea Lees

Overview

With world-patented technology, it is possible to dry sticky substances that cannot be dried with other dryers. Japan primarily produces green tea, including varieties like sencha, gyokuro, kabusecha, tencha, matcha, and gyokurocha. Among these, tencha is ground to make matcha. Green tea consumption trends show a decline in loose-leaf tea and an increase in bottled green tea beverages.

Importance of Drying Green Tea Lees

| Feature | Benefit |

|---|---|

| Prevents Rot and Odor | Drying inhibits bacterial and mold growth, eliminating foul odors. |

| Maintains Nutrient Composition | Low-temperature drying retains nitrogen, phosphorus, and potassium, making it ideal for fertilizer and compost applications. |

| Reduces Waste Volume and Costs | Lower weight decreases industrial waste disposal costs, crucial amid the 2024 trucking issue. |

| Supports Upcycling and Recycling | Dried green tea lees can be used as soil conditioners, compost, livestock feed, or even biochar. |

| Energy-Efficient Drying | Steam-based indirect heating minimizes fuel consumption and operational costs. |

| Decarbonization and Sustainability | No CO2 emissions during drying, supporting carbon neutrality efforts. |

| Continuous Operation | 24-hour automated drying with minimal maintenance due to slow blade rotation (<5 rpm). |

Applications of Dried Green Tea Lees

- Agriculture: Fertilizer, soil conditioner, compost

- Livestock Feed: Used for cattle and pigs

- Biochar & Bio-Coke: Alternative fuel sources through carbonization

- Industrial Use: Ingredient in organic products or energy generation

Q&A Section

Q1: Why is it important to dry green tea lees?

A: Moist tea lees decompose due to microbial activity, producing foul odors and harmful bacteria. Drying prevents this and makes them reusable.

Q2: How does KENKI DRYER maintain the quality of dried tea lees?

A: Its low-temperature steam drying process ensures minimal nutrient loss, making the dried material suitable for composting and soil conditioning.

Q3: Can dried tea lees be used as an alternative fuel?

A: Yes, they can be processed into biochar or bio-coke, which are used in steel and foundry industries as coke substitutes.

Q4: What makes KENKI DRYER energy efficient?

A: It uses indirect steam heating, requiring minimal steam input and utilizing surplus steam for cost savi

Q5: How does KENKI DRYER support decarbonization?

A: Since it operates without burning fossil fuels and can utilize electric or hydrogen boilers, it achieves zero CO2 emissions during drying.

Conclusion

KENKI DRYER is the ideal solution for drying green tea lees, offering an eco-friendly, cost-effective, and highly efficient drying process. With 11 patents across 8 countries, it provides a sustainable method for recycling and upcycling green tea waste. If you need a reliable drying solution, KENKI DRYER is the best choice for optimizing waste management.

For more information or a consultation, contact us today!

Importance of Drying Green Tea Lees

| Feature | Benefit |

|---|---|

| Prevents Rot and Odor | Drying inhibits bacterial and mold growth, eliminating foul odors. |

| Maintains Nutrient Composition | Low-temperature drying retains nitrogen, phosphorus, and potassium, making it ideal for fertilizer and compost applications. |

| Reduces Waste Volume and Costs | Lower weight decreases industrial waste disposal costs, crucial amid the 2024 trucking issue. |

| Supports Upcycling and Recycling | Dried green tea lees can be used as soil conditioners, compost, livestock feed, or even biochar. |

| Energy-Efficient Drying | Steam-based indirect heating minimizes fuel consumption and operational costs. |

| Decarbonization and Sustainability | No CO2 emissions during drying, supporting carbon neutrality efforts. |

| Continuous Operation | 24-hour automated drying with minimal maintenance due to slow blade rotation (<5 rpm). |

Applications of Dried Green Tea Lees

- Agriculture: Fertilizer, soil conditioner, compost

- Livestock Feed: Used for cattle and pigs

- Biochar & Bio-Coke: Alternative fuel sources through carbonization

- Industrial Use: Ingredient in organic products or energy generation

Q&A Section

Q1: Why is it important to dry green tea lees?

A: Moist tea lees decompose due to microbial activity, producing foul odors and harmful bacteria. Drying prevents this and makes them reusable.

Q2: How does KENKI DRYER maintain the quality of dried tea lees?

A: Its low-temperature steam drying process ensures minimal nutrient loss, making the dried material suitable for composting and soil conditioning.

Q3: Can dried tea lees be used as an alternative fuel?

A: Yes, they can be processed into biochar or bio-coke, which are used in steel and foundry industries as coke substitutes.

Q4: What makes KENKI DRYER energy efficient?

A: It uses indirect steam heating, requiring minimal steam input and utilizing surplus steam for cost savi

Q5: How does KENKI DRYER support decarbonization?

A: Since it operates without burning fossil fuels and can utilize electric or hydrogen boilers, it achieves zero CO2 emissions during drying.

Conclusion

KENKI DRYER is the ideal solution for drying green tea lees, offering an eco-friendly, cost-effective, and highly efficient drying process. With 11 patents across 8 countries, it provides a sustainable method for recycling and upcycling green tea waste. If you need a reliable drying solution, KENKI DRYER is the best choice for optimizing waste management.

For more information or a consultation, contact us today!

Low temperature drying of green tea lees with KENKI DRYER

Most of the tea produced in Japan is green tea. There are several types of green tea, including sencha, gyokuro, kabusecha, tencha, matcha, and gyokurocha. Tencha and matcha are different: matcha is made by grinding tencha into a fine powder in a tea mill or similar device. In addition, gyokuro, kabusecha and tencha are collectively referred to as “aoicha”.

Consumption of green tea (leaf tea) is declining, while consumption of green tea beverages is increasing.

The annual amount spent per household on green tea (leaf tea) and tea beverages is decreasing for leaf tea but increasing for tea beverages. The total amount is about 11,000 yen and has remained the same in recent years. Leaf tea is tea made from tea leaves, while green tea beverages are beverages made from green tea leaves, such as sencha, which are extracted or infused and then bottled.

If green tea lees are left in a state with a lot of moisture, they will begin to rot due to the activity of microorganisms (especially bacteria and mold) contained in them. These microorganisms use the moisture and nutrients contained in the green tea lees to multiply, producing gas and foul odors, causing the green tea lees to rot and giving rise to foul odors and pathogenic bacteria. Drying is an effective way to solve these problems.

Green tea waste is rich in nutrients such as nitrogen, phosphorus and potassium and is used as fertilizer, compost and soil conditioner in tea gardens and fields. They are also used as feed for livestock such as cattle and pigs.

The upcycling and recycling of organic waste such as green tea lees is becoming more and more important from the perspective of environmental protection and decarbonization, and the demand for it will only increase.

The heat source for KENKI DRYER is steam from a boiler, and it is a low-temperature indirect drying process. Since it is a low-temperature drying process, there is little change in the composition of the green tea lees, so it can be effectively used for upcycling, and zero-emission drying is possible.

Drying green tea lees reduces their weight, which in turn reduces the amount of waste materials produced, which in turn reduces the cost of industrial waste, which is rising due to the recent trucking problem in 2024.

Wood is currently in short supply in Japan. The use of dried beverage lees such as barley tea lees as fuel instead of wood, or the use of dried beverage lees as biochar or bio-coke by carbonization, is attracting much attention. For example, bio-coke can be used as a reductant or deoxidizer to replace coke in the steel and foundry industries.

Biochar and bio-coke are carbonized materials made from biological resources that are effective in revitalizing organisms and improving the environment. We can provide carbonization services using our Biogreen pyrolysis equipment, which does not use fossil fuels and does not emit CO2, a greenhouse gas, from the equipment.

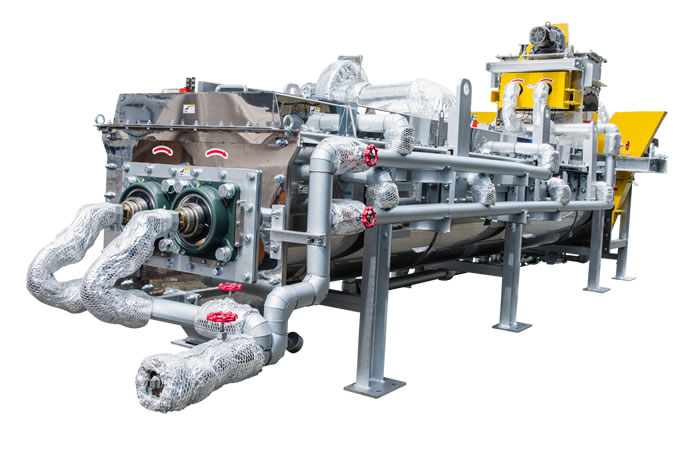

KENKI DRYER, with 11 patents in 8 countries, is an indirect steam dryer, but it is a completely unique product that is different in structure from other similar indirect steam dryers. The KENKI DEYER uses steam as a heat source, but its high drying heat efficiency means that less steam is used. The use of excess steam is not costly in terms of fuel, and the dryer does not emit carbon dioxide during drying, allowing for decarbonized drying. Alternatively, by installing an electric boiler, no greenhouse gases or CO2 emissions are generated during drying.

In addition, there have been no problems since it was put into operation, and because the dryer’s main body blades rotate at a very slow speed of 5 RPM or less, there is little wear on the parts, making maintenance easy and inexpensive. The KENKI DRYER is a continuous drying system that stores and dries the product to be dried and is not a batch system. Therefore, it is easy to manage and can operate unattended 24 hours a day.

If you have any questions or concerns, please contact us. We will be happy to suggest the most suitable dryer for your company’s needs.

Our KENKI DRYER has been patented in 8 countries and is good at drying sticky substances that other dryers cannot dry. It has no problems after installation, is easy to maintain, and has low operating costs. Companies that have implemented it have received positive feedback for its high performance and durability, as well as its ability to improve productivity without uneven drying and without the need for manual labor.

KENKI DRYER can dry sticky and adhesive materials that others cannot dry. KENKI DRYER is a breakthrough drying device with a total of 11 patents (2 in Japan and 9 in 7 overseas countries). Please consider KENKI DRYER for your high moisture organic waste dryer, sludge dryer, slurry dryer, methane fermentation digestate dryer, and waste upcycling or recycling dryer.

KENKI DRYER has been granted 11 patents in 8 countries (Japan, Taiwan, USA, France, Germany, UK, Switzerland, Canada).

Why KENKI DRYER is Chosen for Green Tea Dregs Dryers

Overview

With world-patented technology, it is possible to dry sticky substances that cannot be dried with other dryers. Japan primarily produces green tea, including varieties like sencha, gyokuro, kabusecha, tencha, matcha, and gyokurocha. Among these, tencha is ground to make matcha. Green tea consumption trends show a decline in loose-leaf tea and an increase in bottled green tea beverages.

Why Choose KENKI DRYER for Drying Green Tea Dregs

KENKI DRYER is the preferred solution for drying green tea dregs due to its world-patented technology that allows for drying sticky substances that other dryers cannot handle. With its low-temperature indirect steam drying method, it preserves the nutritional value of green tea dregs, making them ideal for recycling and upcycling applications. Additionally, its efficient drying process prevents microbial activity, foul odors, and waste disposal issues.

Importance of Drying Green Tea Lees

| Feature | Benefit |

|---|---|

| Prevents Rot and Odor | Drying inhibits bacterial and mold growth, eliminating foul odors. |

| Maintains Nutrient Composition | Low-temperature drying retains nitrogen, phosphorus, and potassium, making it ideal for fertilizer and compost applications. |

| Reduces Waste Volume and Costs | Lower weight decreases industrial waste disposal costs, crucial amid the 2024 trucking issue. |

| Supports Upcycling and Recycling | Dried green tea lees can be used as soil conditioners, compost, livestock feed, or even biochar. |

| Energy-Efficient Drying | Steam-based indirect heating minimizes fuel consumption and operational costs. |

| Decarbonization and Sustainability | No CO2 emissions during drying, supporting carbon neutrality efforts. |

| Continuous Operation | 24-hour automated drying with minimal maintenance due to slow blade rotation (<5 rpm). |

Applications of Dried Green Tea Lees

- Agriculture: Fertilizer, soil conditioner, compost

- Livestock Feed: Used for cattle and pigs

- Biochar & Bio-Coke: Alternative fuel sources through carbonization

- Industrial Use: Ingredient in organic products or energy generation

Q&A Section

Q1: Why is it important to dry green tea lees?

A: Moist tea lees decompose due to microbial activity, producing foul odors and harmful bacteria. Drying prevents this and makes them reusable.

Q2: How does KENKI DRYER maintain the quality of dried tea lees?

A: Its low-temperature steam drying process ensures minimal nutrient loss, making the dried material suitable for composting and soil conditioning.

Q3: Can dried tea lees be used as an alternative fuel?

A: Yes, they can be processed into biochar or bio-coke, which are used in steel and foundry industries as coke substitutes.

Q4: What makes KENKI DRYER energy efficient?

A: It uses indirect steam heating, requiring minimal steam input and utilizing surplus steam for cost savi

Q5: How does KENKI DRYER support decarbonization?

A: Since it operates without burning fossil fuels and can utilize electric or hydrogen boilers, it achieves zero CO2 emissions during drying.

Conclusion

KENKI DRYER is the ideal solution for drying green tea lees, offering an eco-friendly, cost-effective, and highly efficient drying process. With 11 patents across 8 countries, it provides a sustainable method for recycling and upcycling green tea waste. If you need a reliable drying solution, KENKI DRYER is the best choice for optimizing waste management.

For more information or a consultation, contact us today!

Test case / Drying green tea lees, low-temperature drying of high-moisture green tea lees for upcycling

Test Results / Drying Green Tea Cake, Low-temperature Drying of High-moisture Green Tea Cake for Upcycling

- Material to be dry: High moisture Green tea lees

- Purpose of drying: Upcycling, Reducing industrial waste cost and amount

- Moisture content: 70.2%W.B. before drying, 4.9%W.B. after drying

- Requirements for dryer: Low temperature drying with minimal ingredient changes. To prevent clogging inside the dryer caused by the stickiness and adhesiveness. Automated continuous operation with no operator attended. Machine cost can be recovered in short term.

- Test result: OK

| Please consider KENKI DRYER for drying of sticky materials, adhesive materials and materials in liquid state that no other dryer can deal with. |

| Initial, running and maintenance costs are low because of its simple structure based on internationally patented technology. |

| For sludge drying, costs of our dryers are estimated to be retrieved within 2, 3 years by reducing industrial waste disposal cost. |

| For raw material slurry drying, laborious works of manual operation will be decreased significantly by replacing box shaped compartment tray dryer with our dryer |

| In case of organic wastes drying, the waste can be recycled as fuel, fertilizer, soil conditioner and feedstuff after being dried. |

| Company site No more trouble. Conveyor, Industrial environmental equipment and apparatus | http://kenki-corporation.com |

| Pyrolyzer Biogreen A pyrolyser with internationally patented technology which use no fire | http://www.biogreen-energy.com |

You must be logged in to post a comment.