Barley tea lees drying, Low temperature drying for upcycling barley tea lees that others cannot dry / KENKI DRYER / Barley tea lees dryer, Upcycling dryer

Why KENKI DRYER is Chosen for Barley Tea Lees Drying Processing

Summary

KENKI DRYER stands out as the preferred solution for drying barley tea lees due to its unique patented technology that effectively addresses the specific challenges of processing these materials. The dryer’s indirect steam drying system operates at low temperatures, preserving the nutritional composition of barley tea lees and enabling their upcycling into valuable products.

Key Advantages of KENKI DRYER for Barley Tea Lees

Technical Advantages

- Handles Sticky Substances: Overcomes the challenge of sugar and starch in barley tea lees that typically cause clogging in conventional dryers

- Low-Temperature Processing: Preserves nutritional composition, including polyphenols and vitamin C

- Indirect Steam Drying: Uses patented technology (11 patents across 8 countries) that differs from other indirect steam dryers

- Low Maintenance: Slow blade rotation (5 RPM or less) reduces wear on parts, making maintenance easy and inexpensive

- Continuous Operation: Unlike batch systems, enables 24-hour unattended operation

Environmental Benefits

- Eco-Friendly: Uses steam as heat source with high drying heat efficiency, consuming less energy

- Decarbonized Drying: Can operate with electric or hydrogen fuel boilers for zero greenhouse gas emissions

- Waste Reduction: Decreases industrial waste volume and associated costs

Business Benefits

- Upcycling Potential: Dried lees can be converted into livestock feed, fertilizer, cosmetic ingredients, and health food components

- Upcycling Potential: Dried lees can be converted into livestock feed, fertilizer, cosmetic ingredients, and health food components

- Cost Reduction: Reduces industrial waste disposal costs, which are rising due to 2024 trucking issues

Key Features and Benefits

KENKI DRYER uses only a very small amount of steam for drying across all applications. This results in low running costs. If your facility has surplus or excess steam, it can be used without incurring additional fuel expenses, making the system even more economical and sustainable.

| Feature | KENKI DRYER Advantage |

|---|---|

| Patented Technology | 11 patents across 8 countries (Japan, Taiwan, USA, France, Germany, UK, Switzerland, Canada) |

| Operational Speed | Slow rotation (≤5 RPM) minimizing wear and maintenance needs |

| Temperature | Low-temperature drying preserving nutritional content |

| Material Handling | Effectively processes sticky substances that clog other dryers |

| Environmental Impact | Can achieve zero carbon emissions with appropriate boiler selection |

| Operation Mode | Continuous system allowing 24-hour unattended operation |

| Post-Processing Benefits | Enables upcycling into multiple valuable products |

By converting barley tea lees into valuable resources rather than waste, KENKI DRYER supports sustainable business practices while creating new revenue opportunities from what would otherwise be a disposal challenge.

Common Questions & Answers about KENKI DRYER for Barley Tea Lees

Q: Why can’t conventional dryers effectively process barley tea lees?

A: Barley tea lees contain sugars and starches that cause them to stick to dryer interiors, especially at low temperatures, leading to clogging and discharge problems.

Q: How does KENKI DRYER preserve the nutritional value of barley tea lees?

A: Its indirect drying system uses steam at low temperatures, minimizing compositional changes during the drying process.

Q: What happens if barley tea lees aren’t properly dried?

A: High moisture content leads to bacterial and mold growth, causing rotting, foul odors, and potential pathogen development.

Q: What makes KENKI DRYER more sustainable than alternatives?

A: It uses less energy, can operate with zero-emission heat sources, and enables waste upcycling into valuable products.

Q: How reliable is the KENKI DRYER system?

A: The system has “no problems since it was put into operation,” offers easy maintenance due to slow-moving parts, and has received positive feedback for performance and durability.

Conclusion

KENKI DRYER is a patented indirect steam drying system specifically designed to overcome challenges in drying barley tea lees. The system features unique technology that prevents the sticky sugars and starches in barley tea lees from clogging the dryer, allowing for effective low-temperature drying that preserves nutritional content.

Key features include:

- 11 patents across 8 countries

- Low-temperature processing that maintains valuable compounds like polyphenols

- Ability to handle sticky substances that other dryers cannot process

- Low maintenance requirements with slow-moving parts

- Continuous 24-hour unattended operation capability

- Eco-friendly design with low energy consumption and potential zero-emission operation

The dried barley tea lees can be upcycled into various products including livestock feed, fertilizer, cosmetic ingredients, health food components, or alternative fuel sources like biochar. This reduces waste disposal costs while creating potential new revenue streams.

As the market for barley tea expands due to health consciousness, KENKI DRYER offers an efficient solution for processing the resulting waste in an environmentally sustainable manner.

Videos / Low temperature drying for upcycling barley tea lees that others cannot dry

KENKI DRYER is for items that other dryers can’t handle.

KENKI DRYER makes it easy to dry barley tea lees that cannot be dried with other types of dryers.

There are various types of barley tea, and historically, six-row barley, two-row barley, and adlay have been used.

By drying the barley tea lees produced after barley tea production at low temperatures, it is possible to use them as upcycled products with minimal changes in their composition after drying. The KENKI DRYER is an indirect drying system that uses steam as a heat source at low temperatures, so there is minimal change in the composition of the dried material after drying, making it possible to recycle and fully utilize it as an upcycled product.

In recent years, barley tea has attracted renewed attention due to growing health consciousness, and the market is expanding rapidly. Barley tea does not contain caffeine, so it does not have a diuretic effect. In addition, barley tea contains polyphenols, and it is also expected to be effective in preventing lifestyle-related diseases.

Barley tea is also popular in seasons other than summer. However, it is said that there is not as much demand for it in the off-season as there is in the summer. For example, according to a 2019 survey, 88% of people drink barley tea in the summer, while about half of people drink barley tea in the winter.

Barley tea are rich in crude protein, fiber, and minerals, and can be used as livestock feed for cattle and pigs, or as fertilizer, compost, or soil amendment in fields. In addition, dried barley tea lees contain vitamin C and polyphenols, and these ingredients can be useful for beauty and health. For example, they can be used as ingredients in cosmetics and health foods.

Drying barley tea lees reduces their weight, which in turn reduces the amount of waste materials produced, which in turn reduces the cost of industrial waste, which is rising due to the recent trucking problem in 2024.

If barley tea lees are left in a state of high moisture content, they will begin to rot due to the activity of the microorganisms (especially bacteria and mold) they contain. These microorganisms will use the moisture and nutrients contained in the barley tea lees to multiply, and in the process they will produce gas and foul odors, causing the lees to rot and become a source of foul odors and pathogens. Drying is an effective way to solve these problems.

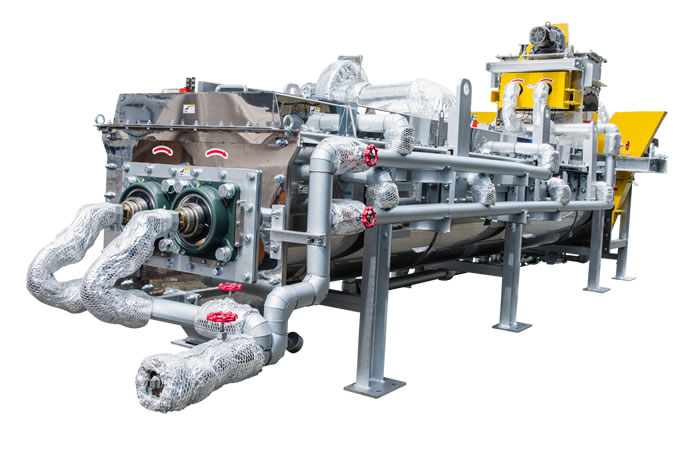

However, in the case of barley tea lees dryers, the sugar and starch contained in barley tea lees can cause them to stick to the inside of the dryer, clogging it and preventing them from being discharged. This effect is particularly noticeable when drying at low temperatures. The KENKI DRYER uses a unique, world-patented technology that makes it possible to easily dry any type of barley tea lees at low temperatures without clogging the dryer, and the dried lees can be easily discharged after drying.

Wood is currently in short supply in Japan. The use of dried beverage lees such as barley tea lees as fuel instead of wood, or the use of dried beverage lees as biochar or bio-coke by carbonization, is attracting much attention. For example, bio-coke can be used as a reductant or deoxidizer to replace coke in the steel and foundry industries.

Biochar and bio-coke are carbonized materials made from biological resources that are effective in revitalizing organisms and improving the environment. We can provide carbonization services using our Biogreen pyrolysis equipment, which does not use fossil fuels and does not emit CO2, a greenhouse gas, from the equipment.

KENKI DRYER, with 11 patents in 8 countries, is an indirect steam dryer, but it is a completely unique product that is different in structure from other similar indirect steam dryers. The KENKI DEYER uses steam as a heat source, but its high drying heat efficiency means that less steam is used. The use of excess steam is not costly in terms of fuel, and the dryer does not emit carbon dioxide during drying, allowing for decarbonized drying. Alternatively, by installing electric boilers or hydrogen fuel boilers, no greenhouse gases or CO2 emissions are generated during drying.

In addition, there have been no problems since it was put into operation, and because the dryer’s main body blades rotate at a very slow speed of 5 RPM or less, there is little wear on the parts, making maintenance easy and inexpensive. The KENKI DRYER is a continuous drying system that stores and dries the product to be dried and is not a batch system. Therefore, it is easy to manage and can operate unattended 24 hours a day.

If you have any questions or concerns, please contact us. We will be happy to suggest the most suitable dryer for your company’s needs.

Our KENKI DRYER has been patented in 8 countries and is good at drying sticky substances that other dryers cannot dry. It has no problems after installation, is easy to maintain, and has low operating costs. Companies that have implemented it have received positive feedback for its high performance and durability, as well as its ability to improve productivity without uneven drying and without the need for manual labor.

KENKI DRYER can dry sticky and adhesive materials that others cannot dry. KENKI DRYER is a breakthrough drying device with a total of 11 patents (2 in Japan and 9 in 7 overseas countries). Please consider KENKI DRYER for your high moisture organic waste dryer, sludge dryer, slurry dryer, beverage lees dryer, and waste upcycling or recycling dryer.

KENKI DRYER has been granted 11 patents in 8 countries (Japan, Taiwan, USA, France, Germany, UK, Switzerland, Canada).

Test case / Low temperature drying for upcycling barley tea lees that others cannot dry

Test Results / Low temperature drying for upcycling barley tea lees that others cannot dry

- Material to be dry: Barley tea lees that others cannot dry

- Purpose of drying: Upcycling, Reducing industrial waste cost and amount

- Moisture content: 64.3%W.B. before drying, 5.7%W.B. after drying

- Requirements for dryer: To prevent clogging inside the dryer caused by the stickiness and adhesiveness. Automated continuous operation with no operator attended. Low temperature drying with little change in composition for upcycling.

- Test result: OK

Beverage lees drying / Brochure

KENKI DRYER which uses International Patented Technology can dry sticky, adhesive and viscous material containing high moisture contents and liquid material that no other company can deal with. It can dry without clogging inside of the dryer and with safe operation which meets no operational trouble. Organic wastes with high moisture contents such as coffee grounds, used tea leaves, soy pulps, livestock excretions, food residues, vegetables, fruits scraps, residues of processed marine product, etc. can be dried smoothly and each of these materials are discharged as valuable product with stable quality after drying.

You must be logged in to post a comment.