Organic waste drying, Low temperature drying for upcycling of highly sticky and adhesive organic waste that is difficult to dry / KENKI DRYER / Organic waste dryer, Upcycling dryer

Why KENKI DRYER is the Premier Choice for Organic Waste Drying

Overview

KENKI DRYER is ideal for drying difficult organic waste such as liquid, sticky, or high-moisture materials. Its patented non-clogging system enables smooth low-temperature steam drying, preserving the material’s composition for reuse. It supports upcycling into compost, fertilizer, feed, or bioplastics, while minimizing steam use and running on surplus steam. With zero CO2 emissions and 24/7 unattended operation, it reduces waste costs and supports decarbonization.

Key Features & Benefits

Core Advantages

- Handles sticky materials others can’t process

- Zero CO2 emissions during operation

- 24/7 unmanned operation capability

- Low maintenance with 5 or less rpm rotation speed

- Uses excess steam at no additional fuel cost

Environmental Impact

- Reduces waste volume and transportation costs

- Supports decarbonization goals

- Enables upcycling to valuable products

- Contributes to circular economy

Process Overview Table

| Input Materials | KENKI DRYER Process | Output Applications |

|---|---|---|

| Sticky organic waste | Steam indirect heating | Fertilizer/Compost |

| High-moisture sludge | Patented anti-clog system | Livestock feed |

| Beverage lees | Continuous 24/7 operation | Bioplastics |

| Industrial waste | Low-temperature drying | Bio-fuel |

| Adhesive materials | <5 rpm rotation speed | Biochar/Bio-coke |

Comparison Matrix

| Feature | KENKI DRYER | Traditional Dryers |

|---|---|---|

| Sticky Material Handling | ✅ Excellent | ❌ Poor (clogs) |

| CO2 Emissions | ✅ Zero | ❌ High |

| Operating Temperature | ✅ Low (preserves quality) | ❌ High (degrades material) |

| Maintenance | ✅ Low cost | ❌ High cost |

| Operation Mode | ✅ Continuous 24/7 | ❌ Batch processing |

Q&A Section

Q: What’s unique about KENKI DRYER?

A: Patented mechanism (11 patents, 8 countries) that prevents clogging with sticky materials, plus zero CO2 emissions during operation.

Q: What materials can it process?

A: Sticky organic waste, high-moisture sludge, beverage lees, and industrial organic waste that other dryers can’t handle.

Q: How does it save costs?

A:

- Uses minimal steam efficiently

- Can utilize excess/surplus steam at no fuel cost

- Low maintenance due to slow rotation

- 24/7 unmanned operation

Q: What products result from drying?

A: Fertilizer, livestock feed, bioplastics, bio-fuel, biochar, and bio-coke.

Q: How reliable is the technology?

A: Proven track record with no start-up problems, positive user feedback, and patent protection across 8 countries.

Conclusion

KENKI DRYER = The solution for “impossible to dry” sticky organic waste + Environmental sustainability + Cost efficiency + Proven reliability

Perfect for companies needing to process challenging organic materials while supporting decarbonization goals.

Videos / Low temperature drying of sticky and adhesive Organic Waste

KENKI DRYER is for items highly sticky and adhesive organic waste that is difficult to dry

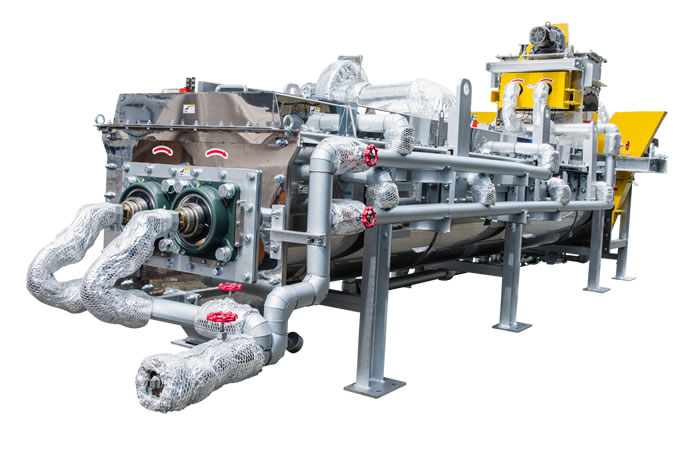

Many organic wastes have strong adhesive qualities and are difficult to dry, and depending on the type of dryer, there are cases where the dryer becomes clogged during the drying process and the organic waste cannot be discharged. With the KENKI DRYER, even if the adhesive qualities are strong and the processing is difficult, and even if the product to be dried has a high water content and is difficult to process, it can be dried easily and smoothly. The KENKI DRYER uses a unique mechanism, which is patented worldwide, and can dry even organic waste with a high water content that has a strong adhesive quality smoothly without clogging the inside of the dryer.

When organic waste is left in a high-moisture state, decomposition is caused by the activity of microorganisms (especially bacteria and molds) contained in the organic waste. These microorganisms use the moisture and nutrients contained in the organic waste to reproduce, producing gases and odors in the process, and the growth of the microorganisms causes decomposition and the development of odors and pathogens. Drying is an effective way to solve these problems.

By reducing the weight of the sludge through drying, the amount of industrial waste produced can be reduced, which in turn helps to reduce the cost of industrial waste, which has increased in recent years due to the 2024 trucking issue and other factors, and also helps to reduce carbon dioxide emissions by reducing the number of trucks used, thereby contributing to environmental protection and decarbonization.

The upcycling and recycling of organic waste from factory production is becoming increasingly important in terms of environmental protection and decarbonization. KENKI DRYER uses steam from a boiler as a heat source for indirect low-temperature drying. Since it dries at low temperatures, the composition of organic waste is hardly changed, and it can be effectively used for upcycling and recycling, making zero-emission drying possible.

After drying, organic waste can be used as fertilizer, compost, soil conditioner, or feed for livestock such as cows and pigs, and bioplastics can be produced from plant-based organic waste as an alternative to petroleum-based plastics.

KENKI DRYER, which has 11 patents in 8 countries, is a steam indirect dryer, but it is a completely unique product with a different structure from other steam indirect dryers. Direct-fire dryers, such as those that use burners, emit carbon dioxide, which is bad for the environment and goes against the trend of decarbonization. Because they dry at high temperatures, they use a lot of fuel and their parts wear out quickly, making them expensive to maintain. KENKI DRYER uses steam as a heat source, but because of its high drying heat efficiency, it only needs a small amount of steam, so you can use the steam you’re currently using, and if you use excess or surplus steam, you don’t have to pay for fuel. The dryer doesn’t emit carbon dioxide when it dries, so you can dry without carbon dioxide. Alternatively, by installing an electric or hydrogen fuel boiler, there is no emission of global warming gases or carbon dioxide CO2 during the drying process.

In addition, there are no problems after start-up, and the rotation speed of the dryer’s main body blades is very slow at less than 5 rpm, so there is little wear and tear on parts, and maintenance is easy and inexpensive. KENKI DRYER is a continuous drying system, in which the drying material to be dried is stored, rather than a batch system. Therefore, operation is simple and unmanned operation is possible 24 hours a day.

Wood is currently in short supply in Japan. The use of dried organic sludge as a fuel instead of wood or the use of dried organic sludge as biochar or bio-coke by carbonization is attracting much attention. For example, bio-coke can be used as a reductant or deoxidizer to replace coke in the steel and foundry industries. Biochar and bio-coke are carbonized materials made from biological resources that are effective in revitalizing organisms and improving the environment. For carbonization, please contact us about Biogreen, our pyrolysis equipment that does not use fossil fuels and does not emit CO2, a greenhouse gas.

If you have any questions or concerns, please let us know. We will be happy to suggest the best dryer for your company’s needs.

Our dryer, ‘KENKI DRYER’, has received 11 patents in 8 countries and is particularly effective at drying sticky materials that others cannot handle. It has no installation problems, is easy to maintain, and has low operating costs. The KENKI DRYER has been well received by companies that have installed it due to its uniform drying, improved productivity with less manpower, high performance and durability.

KENKI DRYER can dry sticky and adhesive materials that others cannot dry. KENKI DRYER is a breakthrough drying device with a total of 11 patents (2 in Japan and 9 in 7 overseas countries). Please consider KENKI DRYER for your high moisture organic waste dryer, sludge dryer, slurry dryer, beverage lees dryer, and waste upcycling or recycling dryer.

KENKI DRYER has been granted 11 patents in 8 countries (Japan, Taiwan, USA, France, Germany, UK, Switzerland, Canada).

Test case / Low temperature drying for upcycling of highly sticky and adhesive organic waste that is difficult to dry

Test Results / Low temperature drying for upcycling of Highly sticky and adhesive organic waste that is difficult to dry

- Material to be dry: Highly sticky and adhesive Organic Waste that is difficult to dry

- Purpose of drying: Upcycling, Industrial waste cost and amount

- Moisture content: 87.8%W.B. before drying, 3.8%W.B. after drying

- Requirements for dryer: To prevent clogging inside the dryer caused by the stickiness and adhesiveness. Automated continuous operation with no operator attended.

- Test result: OK

Organic waste drying / Brochure

No matter how sticky, adhesive and viscous the material is, KENKI DRYER of International Patent can dry it without clogging inside of dryer and with stable operation that no operational trouble occurs because of its unique mechanism. For example, even materials stuck to the blades of one screw, blades of the other screw in the dryer’s body forcibly peels the materials off as they rotate. Since the blades rotate by peeling the material off each other, any sticky, adhesive and viscous material does not adhere to the blade, and the blades continue rotating, peeling, agitating and heating material without stopping while they carries material further. Also, since surface of blades are always renewed and kept clean, heat near the blades is not blocked and it is conducted directly into the materials.

You must be logged in to post a comment.