Coffee grounds drying, Low temperature drying of high moisture coffee grounds for upcycling / KENKI DRYER / Coffee grounds dryer, Upcycling dryer

Why KENKI DRYER is the Optimal Choice for Coffee Grounds Drying

Executive Summary

KENKI DRYER offers a revolutionary solution for coffee grounds drying, combining environmental sustainability with operational efficiency. This patented technology transforms waste coffee grounds into valuable upcycled products while reducing disposal costs and environmental impact.

Key Advantages of KENKI DRYER for Coffee Grounds

Environmental & Sustainability Benefits

- Zero CO2 emissions during drying process

- Enables decarbonized drying operations

- Supports circular economy through waste upcycling

- Reduces transportation costs and truck emissions

- Compatible with electric and hydrogen fuel boilers

Technical Superiority

- Low-temperature indirect steam drying preserves material composition

- High heat efficiency reduces steam consumption

- Continuous operation (24/7 unattended capability)

- Ultra-slow rotation (5 RPM or less) minimizes wear and maintenance

- Handles sticky and adhesive materials that other dryers cannot process

Business Benefits

- Low operating costs due to efficient steam usage

- Minimal maintenance requirements

- Easy management with continuous system design

- Reduces industrial waste disposal expenses

- Creates revenue from upcycled products

Comparison Table: KENKI DRYER vs. Traditional Drying Methods

| Feature | KENKI DRYER | Traditional Dryers |

|---|---|---|

| CO2 Emissions | Zero emissions | High emissions |

| Operating Mode | Continuous 24/7 | Batch processing |

| Maintenance | Low cost, easy | High cost, complex |

| Material Handling | Sticky materials ✓ | Limited capability |

| Heat Source | Steam (efficient) | Various (less efficient) |

| Automation | Unattended operation | Manual supervision |

| Patents | 11 in 8 countries | Standard technology |

Coffee Grounds Transformation Process

| Input | Process | Output Applications |

|---|---|---|

| Wet Coffee Grounds | KENKI Steam Drying | Soil Conditioner |

| High moisture content | Low-temperature treatment | Fertilizer |

| Spoilage risk | Composition preservation | Biofuel |

| Waste disposal cost | Weight reduction | Biodegradable Plastics |

| Biochar/Bio-coke |

Frequently Asked Questions (FAQ)

Q: Why is drying coffee grounds important?

A: Fresh coffee grounds create ideal conditions for bacteria and mold growth due to high organic matter content. Drying prevents spoilage, reduces weight for easier transport, and enables valuable upcycling applications like biofuel and soil conditioner production.

Q: What makes KENKI DRYER different from other coffee grounds dryers?

A: KENKI DRYER’s patented indirect steam technology operates at low temperatures, preserving the coffee grounds’ beneficial properties. Its unique design handles sticky materials that jam other dryers, while offering zero-emission operation and 24/7 automation.

Q: How does KENKI DRYER support environmental goals?

A: The dryer enables complete decarbonization through steam-only operation, reduces transportation emissions by decreasing waste volume, and transforms waste into valuable products like biochar and bio-coke, supporting circular economy principles.

Q: What are the main cost benefits?

A: Users save on industrial waste disposal fees (increasingly expensive due to trucking shortages), reduce maintenance costs through slow-rotation design, and generate revenue from selling dried coffee grounds as fertilizer, fuel, or biochar.

Q: Can KENKI DRYER handle large volumes continuously?

A: Yes, KENKI DRYER operates as a continuous system (not batch), enabling 24/7 unattended operation. This makes it ideal for coffee roasters, cafes, and processing facilities with consistent waste streams.

Q: What quality certifications does KENKI DRYER have?

A: KENKI DRYER holds 11 patents across 8 countries (Japan, Taiwan, USA, France, Germany, UK, Switzerland, Canada), demonstrating its innovative technology and international recognition.

KENKI DRYER for Coffee Grounds: Key Summary

KENKI DRYER is a patented steam-powered drying system (11 patents in 8 countries) that transforms waste coffee grounds into valuable products like fertilizer, biofuel, and biochar. It offers zero CO2 emissions, 24/7 unattended operation, and handles sticky materials that jam other dryers. The system reduces waste disposal costs, prevents spoilage through low-temperature drying, and supports environmental goals by enabling coffee waste upcycling instead of disposal.

Main benefits:

Environmental sustainability, cost savings, continuous operation, and transformation of coffee waste into revenue-generating products.

Videos / Low temperature drying of high moisture coffee grounds for upcycling

KENKI DRYER is for items that other dryers can’t handle.

Coffee grounds are the solid material that remains after coffee beans are ground and coffee is extracted, generally a powdery substance that remains in filters and espresso machines after coffee is brewed. Coffee grounds are typically disposed of as waste, but in recent years, the drying and post-drying uses of coffee grounds have attracted considerable attention.

The dried coffee grounds can be used as soil conditioner, fertilizer, fuel, etc., or as a material for biodegradable plastics.

Leaving coffee grounds in a moist state provides a suitable environment for microorganisms (bacteria and mold) to grow and cause spoilage. Coffee grounds contain high levels of organic matter, which provides a nutrient source for microorganisms and facilitates their growth. In addition, a warm environment increases microbial activity, especially at room temperature and above, which causes coffee grounds to decompose more quickly. Drying is an effective solution to these problems.

KENKI DRYER uses steam as a heat source for low temperature indirect drying, so there is little change in the composition of the dried material after drying, and it can be used as an upcycling product. It is possible to use it as an upcycled product.

Drying coffee grounds to reduce their weight and the amount of waste materials can contribute to environmental protection and decarbonization by reducing the cost of industrial waste, which is increasing due to the recent trucking problem, and by reducing the number of trucks used to transport the waste materials.

Currently, wood is in short supply in Japan. The use of beverage lees, such as coffee grounds after drying, as fuel instead of wood, or the use of biochar or bio coke by carbonizing beverage lees after drying, is attracting a great deal of attention. For example, biochar can be used as activated carbon or soil conditioner, while bio-coke can be used as a reductant or deoxidizer as a substitute for coke in the steel and foundry industries.

Biochar and bio coke are carbonized materials made from biological resources that are effective in revitalizing organisms and improving the environment. We can provide carbonization services using our Biogreen pyrolysis equipment, which does not use fossil fuels and does not emit CO2, a greenhouse gas, so please contact us.

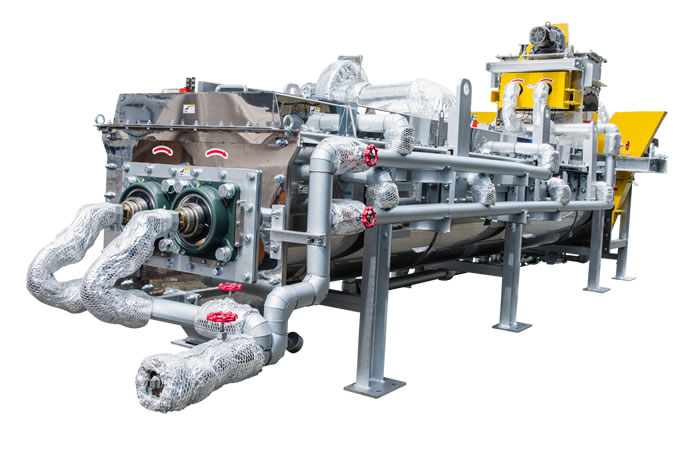

KENKI DRYER, with 11 patents in 8 countries, is an indirect steam dryer, but it is a completely unique product that is different in structure from other similar indirect steam dryers. The KENKI DEYER uses steam as a heat source, but its high drying heat efficiency means that less steam is used. The use of excess steam is not costly in terms of fuel, and the dryer does not emit carbon dioxide during drying, allowing for decarbonized drying. Alternatively, by installing electric boilers or hydrogen fuel boilers, no greenhouse gases or CO2 emissions are generated during drying.

In addition, there have been no problems since it was put into operation, and because the dryer’s main body blades rotate at a very slow speed of 5 RPM or less, there is little wear on the parts, making maintenance easy and inexpensive. The KENKI DRYER is a continuous drying system that stores and dries the product to be dried and is not a batch system. Therefore, it is easy to manage and can operate unattended 24 hours a day.

If you have any questions or concerns, please contact us. We will be happy to suggest the most suitable dryer for your company’s needs.

Our KENKI DRYER has been patented in 8 countries and is good at drying sticky substances that other dryers cannot dry. It has no problems after installation, is easy to maintain, and has low operating costs. Companies that have implemented it have received positive feedback for its high performance and durability, as well as its ability to improve productivity without uneven drying and without the need for manual labor.

KENKI DRYER can dry sticky and adhesive materials that others cannot dry. KENKI DRYER is a breakthrough drying device with a total of 11 patents (2 in Japan and 9 in 7 overseas countries). Please consider KENKI DRYER for your high moisture organic waste dryer, sludge dryer, slurry dryer, beverage lees dryer, and waste upcycling or recycling dryer.

KENKI DRYER has been granted 11 patents in 8 countries (Japan, Taiwan, USA, France, Germany, UK, Switzerland, Canada).

Test case / Low temperature drying of high moisture coffee grounds for upcycling

Test Results / Low temperature drying of high moisture coffee grounds for upcycling

- Material to be dry: High moisture Coffee grounds

- Purpose of drying: Upcycling, Reducing industrial waste cost and amount

- Moisture content: 70.2%W.B. before drying, 2.2%W.B. after drying

- Requirements for dryer: To prevent clogging inside the dryer caused by the stickiness and adhesiveness. Automated continuous operation with no operator attended. Low temperature drying with little change in composition for upcycling.

- Test result: OK

Beverage lees drying / Brochure

KENKI DRYER which uses International Patented Technology can dry sticky, adhesive and viscous material containing high moisture contents and liquid material that no other company can deal with. It can dry without clogging inside of the dryer and with safe operation which meets no operational trouble. Organic wastes with high moisture contents such as coffee grounds, used tea leaves, soy pulps, livestock excretions, food residues, vegetables, fruits scraps, residues of processed marine product, etc. can be dried smoothly and each of these materials are discharged as valuable product with stable quality after drying.

You must be logged in to post a comment.