Liquid Raw materials Slurry drying, Low-temperature production drying of strongly sticky and adhesive liquid raw materials slurry / KENKI DRYER / Slurry dryer, Raw materials dryer

KENKI DRYER: Revolutionary Steam Drying Technology

Executive Summary

KENKI DRYER is an internationally patented industrial drying system (11 patents across 8 countries) that uses saturated steam to efficiently dry sticky, adhesive, and high-moisture materials. It operates continuously at low temperatures, requires minimal maintenance, and produces zero CO2 emissions during operation.

Key Reasons to Choose KENKI DRYER for Slurry Applications

| Feature | Benefit |

|---|---|

| Patented Technology | 11 patents in 8 countries (Japan, Taiwan, USA, France, Germany, UK, Switzerland, Canada) |

| Heat Source | Saturated steam only – environmentally friendly |

| Operating Temperature | Low temperature drying preserves material composition |

| Material Compatibility | Handles highly adhesive, sticky, and liquid slurries without clogging |

| Operation | Continuous 24/7 unattended operation |

| Maintenance | Minimal wear (≤5 RPM blade speed), low cost |

| Drying Quality | Uniform, stable output with consistent moisture levels |

| Environmental Impact | Zero CO2 emissions during drying process |

Technical Advantages

Superior Drying Method

- Combines conduction heat transfer with hot air

- Indirect steam dryer with unique patented structure

- No clogging even with high-adhesion materials

- Penetrates and dries materials thoroughly from inside out

Operational Efficiency

- Continuous system (non-batch)

- No manual labor required

- Easy management and monitoring

- High heat efficiency reduces steam consumption

Sustainability Features

- Can use excess or surplus steam (zero fuel cost)

- Compatible with electric or hydrogen fuel boilers

- No carbon dioxide emissions during operation

- Supports decarbonization goals

Applications

- Raw material processing (food, chemical, pharmaceutical)

- Slurry drying (industrial and manufacturing)

- High moisture organic waste drying

- Sludge treatment and processing

- Beverage lees and residue drying

- Waste upcycling and recycling operations

Frequently Asked Questions

Q: What makes KENKI DRYER different from conventional dryers?

A: KENKI DRYER uses patented technology that prevents clogging with sticky materials, operates at low temperatures to preserve material quality, and uses only steam as a heat source for environmentally friendly operation.

Q: Can it handle liquid or highly adhesive materials?

A: Yes, KENKI DRYER’s patented mechanism allows it to dry even liquid-form and highly sticky materials without clogging, unlike conventional dryers.

Q: Does it require constant supervision?

A: No, KENKI DRYER operates continuously 24/7 without manual intervention, making it ideal for unattended operation.

Q: What are the maintenance requirements?

A: Maintenance is minimal and inexpensive due to the slow rotation speed (≤5 RPM) which reduces wear on parts.

Q: Is it environmentally friendly?

A: Yes, KENKI DRYER produces zero CO2 emissions during operation and can use excess steam or renewable energy sources like electric or hydrogen fuel boilers.

Q: Can it replace existing drying systems?

A: Yes, replacing conventional box-type shelf drying systems with KENKI DRYER significantly simplifies operations and eliminates tedious manual drying tasks.

Q: What about product quality after drying?

A: Low-temperature drying preserves material components with minimal changes, producing uniform, stable finished products suitable for direct shipment.

Q: How energy-efficient is it?

A: The dryer has excellent heat efficiency, requiring less steam than conventional systems and can utilize surplus steam at zero fuel cost.

Why Choose KENKI DRYER?

- Proven technology with international patent protection

- Waste upcycling and recycling materials

- Reduces operational costs and labor requirements

- Improves productivity with consistent quality

- Zero environmental impact during operation

- Long-term durability and reliability

Videos / Liquid Raw materials Slurry Drying

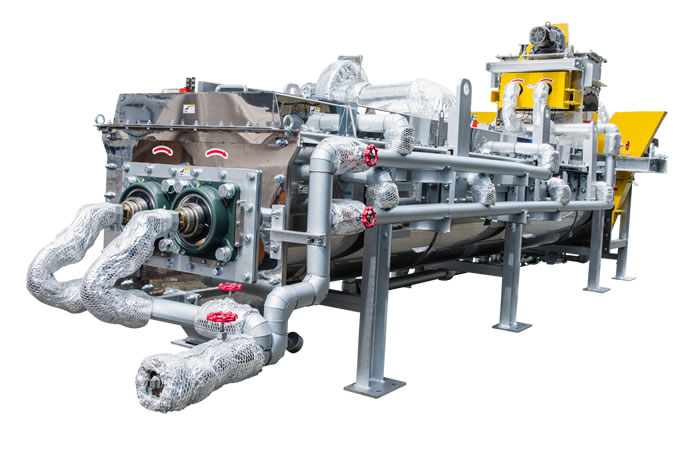

Low-temperature drying of Slurry Raw materials with KENKI DRYER

Even when drying raw material slurry, KENKI DRYER, which has already been granted an international patent, can demonstrate its full potential. Even if the material is highly adhesive or sticky, it will not clog the dryer and can be dried without problems even if it is in liquid form, allowing stable operation. Since saturated steam is used as the heat source and drying is performed at low temperatures, the components of the material being dried do not change and the material can be dried evenly, so there are no problems at all in drying the material. The heat source for drying in KENKI DRYER is only saturated steam. It uses a revolutionary drying method that combines conduction heat transfer and hot air, and is superior in terms of safety and hygiene. It is also able to dry the inside of the drying object to a sufficient degree thanks to its internationally patented technology, and after drying, it is discharged in a very stable and uniform state. It can operate unattended for 24 hours without the need for manual labor. If you replace your conventional box-type shelf drying system with KENKI DRYER, you will find that drying becomes much easier and you will be freed from the tedious task of drying.

Even if the material to be dried has strong adhesion or stickiness and is difficult to dry, KENKI DRYER can dry it easily and evenly. Depending on the type of dryer, slurry materials with strong adhesion or stickiness may become clogged during drying and may not be able to be dried. KENKI DRYER uses a unique mechanism, which is patented worldwide, to enable the smooth drying of any slurry with high adhesion or stickiness, even if it has a high moisture content, without clogging inside the dryer.

And KENKI DRYER dries at low temperatures, so there is little change in the components of the material being dried, making it completely safe to use for drying raw materials. After drying, there is little change in the components of the material being dried, so it can be shipped as a finished product. In addition, after drying, the material to be dried is evenly dried, so a stable product can be produced.

KENKI DRYER, which has 11 patents in 8 countries, is an indirect steam dryer, but it is a completely unique product with a different structure from other indirect steam dryers. Direct-fired dryers, which use burners, etc., emit carbon dioxide, which is bad for the environment and goes against the trend of decarbonization. KENKI DRYER uses steam as its heat source, but because the drying heat efficiency is good, the amount of steam used is small, so you can use the steam you currently use, and if you use excess or surplus steam, there is no fuel cost, and when drying, no carbon dioxide is emitted from the dryer, so you can dry without carbon dioxide. Alternatively, by installing electric boilers or hydrogen fuel boilers, there is no generation of global warming gases or carbon dioxide CO2 at all during drying.

In addition, there are no problems after start-up, and the rotation speed of the dryer’s main body blades is very slow at 5 RPM or less, so there is little wear and tear on parts, making maintenance easy and inexpensive. The KENKI DRYER is a continuous drying system that stores the product to be dried and is not a batch system. As a result, it is easy to manage and can operate unattended 24 hours a day. No human labor is required to install KENKI DRYER.

If you have any questions or concerns, please let us know. We will be happy to suggest the best dryer for your company’s needs.

Our dryer, ‘KENKI DRYER’, has received 11 patents in 8 countries and is particularly effective at drying sticky materials that others cannot handle. It has no installation problems, is easy to maintain, and has low operating costs. The KENKI DRYER has been well received by companies that have installed it due to its uniform drying, improved productivity with less manpower, high performance and durability.

KENKI DRYER, which can dry sticky and adhesive materials that others cannot dry, is a breakthrough dryer with a total of 11 patents (2 in Japan and 9 in 7 foreign countries) and proprietary technology. Please consider KENKI DRYER for your high moisture organic waste dryer, sludge dryer, slurry dryer, beverage lees dryer, waste upcycling and recycling dryer.

KENKI DRYER has been granted 11 patents in 8 countries (Japan, Taiwan, USA, France, Germany, UK, Switzerland, Canada).

Test case / Liquid Raw materials Slurry Drying

Test Results / Liquid Raw materials Slurry Drying

- Material to be dry: Liquid raw material slurry

- Purpose of drying: Product Manufacturing

- Moisture content: 52.2%W.B. before drying, 2.8%W.B. after drying

- Requirements for dryer: To prevent clogging inside the dryer caused by the stickiness and adhesiveness. Low-temperature drying with minimal component changes. Automated continuous operation with no operator attended. Machine cost can be recovered in short term.

- Test result: OK

Slurry drying / Brochure

KENKI DRYER which uses International Patented Technology can dry sticky, adhesive and viscous material containing high moisture contents and liquid material that no other company can deal with. It can dry without clogging inside of the dryer and with safe operation which meets no operational trouble. Organic wastes with high moisture contents such as coffee grounds,used tea leaves, soy pulps, livestock excretions, food residues, vegetables, fruits scraps, residues of processed marine product, etc. can be dried smoothly and each of these materials are discharged as valuable product with stable quality after drying.

You must be logged in to post a comment.