Organic sludge drying, Low temperature drying for strongly sticky and adhesive organic sludge / KENKI DRYER / Sludge dryer, Upcycling dryer

KENKI DRYER: Industrial Sticky Material Drying Solution

What is KENKI DRYER?

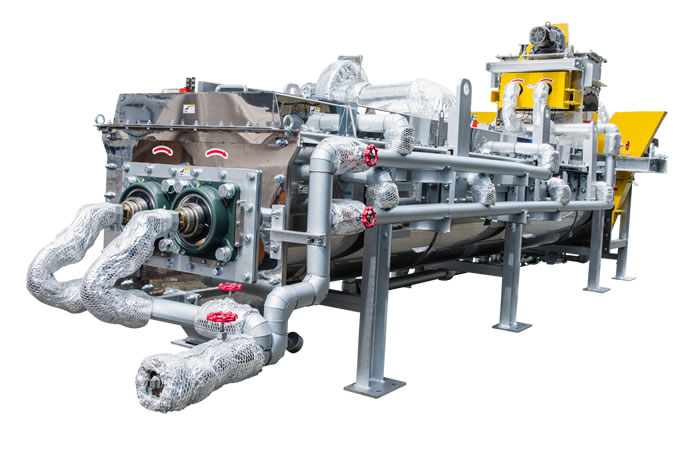

KENKI DRYER is an indirect steam drying system with 11 international patents designed to dry sticky adhesive materials that conventional dryers cannot handle. It features ultra-low 5 rpm blade speed, internal crushing technology, and continuous 24/7 unmanned operation capability.

Key Specifications

| Feature | Specification |

|---|---|

| Patents | 11 across 8 countries (Japan, Taiwan, USA, France, Germany, UK, Switzerland, Canada) |

| Heating | Low-temperature indirect steam (electric boiler option) |

| Blade Speed | 5 rpm or less |

| Operation | Continuous, 24/7 unmanned capable |

| Maintenance | Minimal wear, low cost |

| Emissions | Zero CO₂ during drying |

Core Advantages

- Anti-Clogging: Internal crushing prevents blockages with sticky materials

- Uniform Drying: Complete internal drying, not just surface

- Low Temperature: Preserves material composition for recycling/upcycling

- Cost Efficient: Reduced maintenance, low operating costs, minimal waste volume

- Sustainability: Zero emissions, supports resource recovery (phosphorus extraction),reduces transportation needs

Applications

- Materials: Wastewater sludge, beverage lees, slurry, organic waste

- End Uses: Compost, soil conditioner, fuel, mineral recovery

Why KENKI DRYER?

- Handles sticky materials others cannot

- 11 patents—proven innovation

- Decarbonized operation

- 24/7 unmanned automation

- Lower waste disposal costs

- Enables circular economy initiatives

Quick Comparison

| Aspect | KENKI DRYER | Standard Dryers |

|---|---|---|

| Sticky Materials | Handles easily | Frequent clogging |

| Drying Quality | Complete internal | Surface-only |

| Maintenance | Low (5 rpm) | High |

| Emissions | Zero | Fuel-dependent |

| Unmanned Op. | Yes | Limited |

Frequently Asked Questions (FAQ)

Q: How does KENKI DRYER prevent clogging?

A: Internal crushing and size-reduction technology breaks apart sticky clumps, maintaining particle dispersion and preventing blockages.

Q: Can it run unattended?

A: Yes, 24/7 unmanned continuous operation reduces labor costs and ensures consistent throughput.

Q: What sustainability benefits does it offer?

A: Zero emissions, reduced waste transportation, preserved material composition for recycling, and mineral recovery support (e.g., phosphorus extraction).

Q: What is maintenance like?

A: Minimal—ultra-low 5 rpm speed causes very little wear on mechanical parts, reducing replacement frequency and costs.

Q: Which materials does it handle best?

A: Sticky, adhesive, high-moisture organic waste: wastewater sludge, beverage lees, slurry, and materials that cause clogging in standard dryers.

Q: Is KENKI DRYER right for my facility?

A: Contact our team for consultation. KENKI DRYER suits any operation generating sticky or high-moisture waste requiring drying and recycling.

KENKI DRYER: Industrial Sticky Material Drying Solution

KENKI DRYER is an indirect steam drying system with 11 international patents designed to dry sticky adhesive materials that conventional dryers cannot handle. Its ultra-low 5 rpm blade speed and internal crushing technology prevent clogging while ensuring uniform drying. It operates 24/7 unmanned, requires minimal maintenance, produces zero emissions, and preserves material composition for recycling and mineral recovery (including phosphorus extraction). Perfect for wastewater sludge, beverage lees, and organic waste conversion to compost, fuel, and valuable resources.

Videos / Drying of strongly sticky and adhesive Organic Sludge

Choose KENKI DRYER – The Ultimate Solution for Drying Sticky and Adhesive Materials

When it comes to drying materials with strong sticking or adhesive properties, KENKI DRYER stands apart as a world-leading low-temperature steam dryer with 11 international patents (2 in Japan and 9 across 7 countries). Even if the drying object has a high moisture content and strong adhesiveness—such as dewatered sludge from wastewater treatment plants—KENKI DRYER can dry it smoothly, efficiently, and without clogging, thanks to its unique, patented anti-clogging mechanism.

Unlike conventional dryers that often experience internal clogging and discharge issues, KENKI DRYER’s innovative design ensures consistent and stable drying performance, even with materials that form lumps or adhere to internal surfaces. During the drying process, materials like sludge tend to clump together due to flocculants used in wastewater treatment. KENKI DRYER addresses this by gently crushing and reducing the size of the material, ensuring even heat transfer throughout. As a result, both the surface and the inner parts of the material are completely dried without any unevenness. Low-Temperature Drying for Upcycling and Sustainability

KENKI DRYER operates using low-temperature indirect steam drying, minimizing changes in the composition of materials. This allows dried sludge to be reused or upcycled as compost, soil conditioner, or fuel. Since the system uses steam as the heat source, it enables carbon-free and energy-efficient drying, supporting decarbonization goals. When paired with an electric boiler, the system achieves zero CO₂ emissions during operation.

High Thermal Efficiency and Easy Maintenance

The steam-based heat source offers excellent thermal efficiency, meaning less steam consumption and lower operating costs. The dryer’s slow rotation speed (5 rpm or less) minimizes wear on parts, reducing maintenance costs and extending equipment lifespan. Moreover, the continuous drying system enables fully automatic, 24-hour unmanned operation, enhancing productivity and safety.

Environmental Contribution and Resource Recovery

Drying sludge significantly reduces its weight and volume, cutting industrial waste disposal costs and decreasing CO₂ emissions by reducing truck transportation—an increasingly critical issue amid the logistics challenges of 2024 and beyond.

In Japan, where nearly all mineral resources are imported, recovering valuable minerals and phosphorus from sludge has become a national priority. Upcycling sewage sludge not only contributes to decarbonization and circular economy goals, but also helps secure essential resources such as phosphorus, precious metals, and rare metals for future sustainability.

Why Choose KENKI DRYER

- Successfully dries sticky, adhesive, and high-moisture materials that other dryers cannot handle.

- 11 international patents (Japan, Taiwan, USA, France, Germany, UK, Switzerland, and Canada).

- Low-temperature steam drying for upcycling without altering material composition.

- High thermal efficiency, low maintenance, and easy operation.

- Continuous, fully automated drying for 24-hour operation.

- Environmentally friendly – CO₂-free drying when paired with an electric boiler.

KENKI DRYER is not just a dryer — it is a breakthrough technology that transforms waste into value while supporting sustainability, decarbonization, and resource recovery.

If you would like to learn more or discuss your specific drying requirements, please feel free to contact us. We will be happy to recommend the most suitable KENKI DRYER model for your needs.

Test case / Drying of strongly sticky and adhesive organic sludge

Test Results / Drying of strongly sticky and adhesive organic sludge

- Material to be dry: Strongly sticky and adhesive organic sludge

- Purpose of drying: Upcycling, Industrial waste cost and amount

- Moisture content: 85.7%W.B. before drying, 10.8%W.B. after drying

- Requirements for dryer: To prevent clogging inside the dryer caused by the stickiness and adhesiveness. Automated continuous operation with no operator attended.

- Test result: OK

Organic sludge drying / Brochure

No matter how sticky, adhesive and viscous the material is, KENKI DRYER of International Patent can dry it without clogging inside of dryer and with stable operation that no operational trouble occurs because of its unique mechanism. For example, even materials stuck to the blades of one screw, blades of the other screw in the dryer’s body forcibly peels the materials off as they rotate. Since the blades rotate by peeling the material off each other, any sticky, adhesive and viscous material does not adhere to the blade, and the blades continue rotating, peeling, agitating and heating material without stopping while they carries material further. Also, since surface of blades are always renewed and kept clean, heat near the blades is not blocked and it is conducted directly into the materials.

You must be logged in to post a comment.