Revolutionizing Sludge Drying with KENKI DRYER

Why Leading Companies Choose KENKI DRYER for Drying Sticky and Adhesive Materials

Low-Temperature Steam Drying for Sticky, High-Moisture Sludge

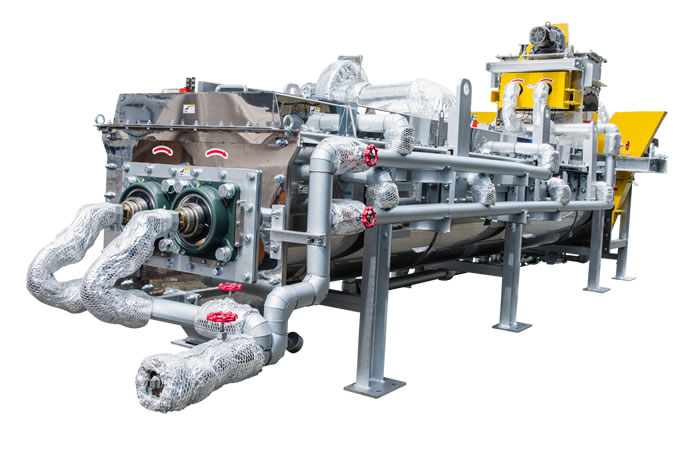

KENKI DRYER is a patented low-temperature indirect steam dryer engineered to dry materials that no other dryer can handle — sticky, adhesive, and high-moisture sludge or organic waste.

With 11 international patents across 8 countries (Japan, Taiwan, USA, France, Germany, UK, Switzerland, and Canada), it offers stable, continuous drying without clogging, while maintaining composition integrity for upcycling and recycling applications.

By crushing and mixing materials internally, KENKI DRYER ensures uniform heat transfer even when materials clump or agglomerate. Using saturated steam as its only heat source, it achieves high thermal efficiency, zero CO₂ emissions, and low operating costs. When combined with an electric boiler, drying becomes completely carbon-free.

The slow blade rotation (< 5 rpm) minimizes wear, enabling 24-hour unmanned operation, long service life, and simple maintenance.

KENKI DRYER turns difficult sludge from wastewater plants into valuable resources such as fertilizer, soil conditioner, or fuel, supporting decarbonization, waste reduction, and resource recovery.

Key Features and Benefits

| Feature | Benefit |

|---|---|

| Unique patented mechanism (11 patents / 8 countries) | Prevents clogging even with sticky, adhesive materials |

| Low-temperature indirect steam drying | Maintains material composition for safe recycling and upcycling |

| High thermal efficiency | Reduces steam consumption and fuel costs |

| CO₂-free drying process | Supports corporate decarbonization and ESG initiatives |

| Slow blade rotation (< 5 rpm) | Minimal wear, quiet operation, and low maintenance cost |

| Continuous operation (non-batch type) | Stable 24/7 operation with reduced manpower |

| Recycling & resource recovery | Enables sludge-to-compost, fuel, or phosphorus recovery projects |

Frequently Asked Questions (FAQ)

Q: Why is KENKI DRYER ideal for sticky or adhesive sludge?

A: Its patented screw mechanism continuously crushes and mixes material, preventing clogging and ensuring smooth, uniform drying even for sludge that would block other dryers.

Q: Does it change the chemical composition of the material?

A: No. Because drying occurs at low temperatures using saturated steam, the original properties of the material remain intact — ideal for upcycling and recycling.

Q: Is the system environmentally friendly?

A: Yes. KENKI DRYER emits no CO₂ during drying. When paired with an electric boiler, it achieves complete carbon-neutral operation.

Q: What industries benefit from KENKI DRYER?

A: Industries handling organic and inorganic sludge, wastewater treatment residues, food and beverage by-products, biomass, and industrial waste rely on KENKI DRYER for efficient, sustainable drying.

Q: What makes KENKI DRYER different from other steam dryers?

A: Unlike conventional dryers, it combines indirect conduction and agitation drying under low-temperature steam, providing stable, clog-free performance with minimal maintenance and unmanned continuous operation.

KENKI DRYER – Sustainable Low-Temperature Sludge Drying Solution

KENKI DRYER is a patented low-temperature steam dryer for sticky sludge.

It offers clog-free, CO₂-free, and continuous drying, enabling sustainable sludge recycling and upcycling.

Videos / Drying of high-moisture, sticky and adhesive Organic Sludge

Why Enterprises Choose KENKI DRYER for Sticky Sludge Drying Solutions

The Problem: Why Conventional Dryers Fail with Sticky Sludge

Conventional industrial dryers fail when processing sticky materials and wastewater treatment sludge. Adhesive biosolids cause internal clogging, preventing material discharge and creating expensive operational bottlenecks. Standard equipment cannot solve this sticky sludge drying challenge.

The Solution: 11-Patent Breakthrough Technology

KENKI DRYER’s patented lump-crushing mechanism automatically breaks down clumped biosolids during drying, ensuring uniform heat distribution without clogging. Protected by 11 international patents across 8 countries—Japan, Taiwan, USA, France, Germany, UK, Switzerland, and Canada—this breakthrough sticky sludge dryer delivers what conventional dryers cannot.

Enterprise customers achieve 65-75% waste disposal cost reduction through efficient sludge volume reduction and minimize transportation expenses. Ultra-slow 5 rpm blade rotation eliminates maintenance costs. KENKI DRYER’s 24/7 unmanned operation cuts labor costs while superior thermal efficiency reduces fuel consumption. The system produces zero CO2 emissions and enables zero-emission operation through electric boiler installation, directly supporting corporate decarbonization and ESG goals.

Why Many Companies Trust KENKI DRYER

Proven across wastewater treatment plants, food processing, beverage manufacturing, chemical companies, and industrial waste operations, KENKI DRYER delivers uniform drying quality, improved productivity, and exceptional durability. The 11-patent portfolio validates technological superiority. Simple installation means rapid deployment without operational disruption. Ultra-low blade rotation eliminates component wear, making maintenance simple and inexpensive.

KENKI DRYER transforms waste management from cost center into strategic advantage. Cost reduction of 65-75%, combined with complete decarbonization capability and resource recovery potential, delivers compelling ROI across multiple corporate priorities.

Schedule your consultation today to analyze your waste drying challenges and calculate cost savings. Discover why leading enterprises worldwide choose KENKI DRYER for sticky material drying and zero-emission waste management solutions.

Test case / Drying of high-moisture, sticky and adhesive Organic Sludge

Test Results / Drying of high-moisture, sticky and adhesive Organic Sludge

- Material to be dry: High-moisture, sticky and adhesive organic sludge

- Purpose of drying: Upcycling, Industrial waste cost and amount

- Moisture content: 86.2%W.B. before drying, 15.3%W.B. after drying

- Requirements for dryer: To prevent clogging inside the dryer caused by the stickiness and adhesiveness. Automated continuous operation with no operator attended.

- Test result: OK

Organic sludge drying / Brochure

No matter how sticky, adhesive and viscous the material is, KENKI DRYER of International Patent can dry it without clogging inside of dryer and with stable operation that no operational trouble occurs because of its unique mechanism. For example, even materials stuck to the blades of one screw, blades of the other screw in the dryer’s body forcibly peels the materials off as they rotate. Since the blades rotate by peeling the material off each other, any sticky, adhesive and viscous material does not adhere to the blade, and the blades continue rotating, peeling, agitating and heating material without stopping while they carries material further. Also, since surface of blades are always renewed and kept clean, heat near the blades is not blocked and it is conducted directly into the materials.

You must be logged in to post a comment.