Black Tea Lees Drying & Upcycling Solution— Zero-Emission, No-Clog Drying with KENKI DRYER

The Only Dryer That Can Handle Black Tea Lees

Business Challenge: Sticky, High-Moisture Tea Lees

Beverage manufacturers generate large volumes of wet, sticky tea lees that spoil quickly, cause odor, increase waste cost, and clog conventional dryers. At the same time, companies seek decarbonized, resource-efficient solutions for waste reduction.

Black tea lees contain flavonoids, catechins, and theaflavins, offering deodorizing, antioxidant, and soil-enriching benefits—but only if dried gently at low temperatures.

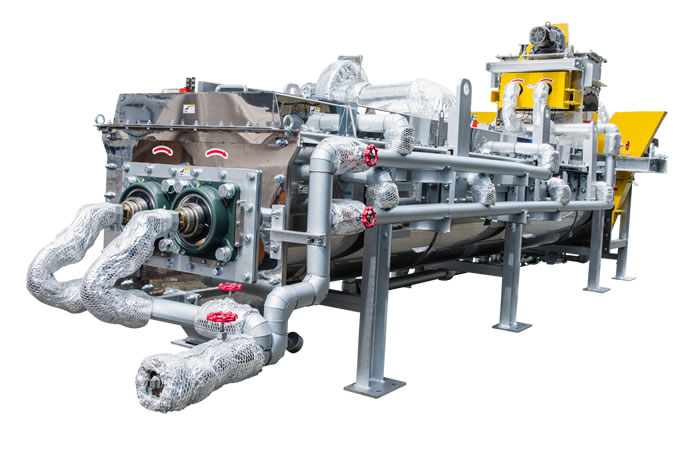

KENKI DRYER: The Only Dryer for Sticky Tea Lees

With 11 patents in 8 countries, KENKI DRYER uses low-temperature indirect steam drying, enabling:

- No clogging, even with sticky and adhesive tea lees

- Zero CO₂ emissions (steam, electric, or hydrogen boilers)

- Preservation of nutrients and deodorizing compounds

- 24/7 continuous, unattended operation

- Very low maintenance (blade rotation ≤5 RPM)

This allows companies to convert tea waste into fertilizer, deodorant material, biomass fuel, or biochar.

Value of Dried Tea Lees

| Use Case | Benefit |

|---|---|

| Fertilizer / soil amendment | Adds organic nutrients & improves soil |

| Deodorant material | Catechins & theaflavins neutralize odor |

| Biomass fuel | Alternative to wood (high demand in Japan) |

| Biochar feedstock | Can replace coke in steel/foundry industries |

| Reduced waste cost | Lower weight & volume → fewer trucks |

Frequently Asked Questions

Q: Why do other dryers fail with tea lees?

A: Because tea lees are sticky and adhesive, causing clogging and burning in conventional dryers.

Q: Why low-temperature drying?

A: It preserves antioxidants, deodorizing compounds, and nutrients, maximizing upcycling value.

Q: Can drying be CO₂-free?

A: Yes. Using steam, electric, or hydrogen boilers, KENKI DRYER operates with zero CO₂ emissions.

Q: Can tea lees be turned into biochar?

A: Yes. After drying, they can be carbonized using Biogreen pyrolysis.

Q: What industries benefit from dried barley tea lees?

A: Multiple sectors including agriculture (feed/fertilizer), energy (biofuel/bio-coke), manufacturing (steel/foundry reductants), and consumer goods (cosmetics/health supplements).

Q: Is the system expensive to operate and maintain?

A: No. Ultra-low blade speed (≤5 RPM) minimizes wear, excess steam use is fuel-efficient, and the continuous system operates unattended 24/7. Users report low maintenance costs and high ROI.

Q: How does bio-coke from barley tea lees work?

A: Dried lees can be carbonized into bio-coke using Biogreen pyrolysis equipment (zero fossil fuel, zero CO2). This bio-coke replaces traditional petroleum coke as a reductant in steel and foundry industries.

Q: What happens if barley tea lees aren’t dried?

A: High-moisture lees quickly rot due to bacterial and mold activity, producing foul odors and pathogens. This creates health hazards and increases waste disposal problems.

Conclusion

KENKI DRYER is a patented low-temperature steam dryer designed for sticky tea lees, enabling zero-emission drying, odor control, waste cost reduction, and high-value upcycling into fertilizer, fuel, and biochar.

Videos / The Only Dryer That Can Handle Black Tea Lees

Black Tea Lees Drying & Upcycling Solution

Growing Tea Production and Waste Challenges

Demand for bottled black tea continues to rise, driven by health awareness and lifestyle changes. As production increases, beverage manufacturers face a growing burden of wet, sticky tea lees that spoil quickly, generate odor, and increase industrial waste costs. Effective drying has become essential for hygiene, cost reduction, and sustainability.

Functional Value Contained in Black Tea Lees

Black tea is rich in flavonoids, catechins, and theaflavins, providing antioxidant, antimicrobial, and deodorizing functions. These compounds can be reused in fertilizers, soil conditioners, and deodorant materials—but only when dried gently at low temperatures to preserve their properties.

Why Wet Tea Lees Spoil Quickly

High moisture creates ideal conditions for bacteria and mold to grow, producing gases, foul odors, and pathogens. Spoilage also increases weight, transport frequency, and disposal cost. Drying eliminates these issues while stabilizing the material for reuse.

KENKI DRYER: The Only Reliable Dryer for Sticky Tea Lees

KENKI DRYER, protected by 11 patents in 8 countries, uses indirect steam to dry at low temperatures without clogging, burning, or changing composition. The system operates CO₂-free, using steam or optional electric/hydrogen boilers. With slow blade rotation (≤5 RPM), wear is minimal, maintenance is low, and 24/7 unattended operation is possible.

Transforming Tea Lees into Valuable Resources

Dried tea lees can be reused as fertilizer, deodorant material, biomass fuel, or further processed into biochar using our Biogreen pyrolysis system. Biochar is increasingly demanded as a replacement for coke in steel and foundry industries, supporting decarbonization and circular manufacturing.

Environmental and Economic Advantages

Low-temperature drying reduces waste volume, transportation frequency, and CO₂ emissions. Because steam use is efficient, operating costs are low—especially when using surplus steam. KENKI DRYER enables companies to meet sustainability goals while improving productivity and reducing manual labor.

Proven Reliability and Customer Satisfaction

Companies that adopted KENKI DRYER report highly stable operation, uniform drying quality, lower running costs, and long-term durability. It consistently dries materials that other dryers cannot handle, making it the preferred choice for tea lees, sludge, slurry, and organic waste.

Test case / Drying Black Tea Lees for Upcycling

Test Results / Drying Black Tea Lees for Upcycling

- Material to be dry: Black tea lees

- Purpose of drying: Upcycling, Reducing industrial waste cost and amount

- Moisture content: 82.2%W.B. before drying, 4.9%W.B. after drying

- Requirements for dryer: To prevent clogging inside the dryer caused by the stickiness and adhesiveness. Automated continuous operation with no operator attended. Low temperature drying with little change in composition for upcycling.

- Test result: OK

Beverage lees drying / Brochure

KENKI DRYER which uses International Patented Technology can dry sticky, adhesive and viscous material containing high moisture contents and liquid material that no other company can deal with. It can dry without clogging inside of the dryer and with safe operation which meets no operational trouble. Organic wastes with high moisture contents such as coffee grounds, used tea leaves, soy pulps, livestock excretions, food residues, vegetables, fruits scraps, residues of processed marine product, etc. can be dried smoothly and each of these materials are discharged as valuable product with stable quality after drying.

You must be logged in to post a comment.