Organic sludge drying / KENKI DRYER: The Ultimate Solution for Drying Sticky, Adhesive, and High-Moisture Sludge

Advanced Patented Technology for No-Clogging, Low-Temperature, and High-Efficiency Drying

Dry the Undryable - Solve Sludge Problems Instantly

Companies often struggle with sticky, adhesive sludge that clogs conventional dryers and prevents smooth discharge.

KENKI DRYER, backed by 11 international patents, delivers completely clog-free, stable drying even for the most difficult wastewater sludge.

Patented Technology for Uniform, Full-Depth Drying

Flocculated sludge forms lumps that standard dryers cannot dry internally.

KENKI DRYER uses a unique crushing and size-reduction mechanism to break lumps, improve heat transfer, and ensure uniform drying from surface to core.

Low-Temperature Steam Drying for High-Value Upcycling

Using saturated steam at low temperatures, KENKI DRYER preserves material composition, making dried sludge ideal for compost, soil conditioners, fuel, and recycling.

A perfect system for turning waste into valuable resources.

Decarbonized, Cost-Efficient 24/7 Operation

With superior thermal efficiency, KENKI DRYER requires minimal steam and can achieve zero CO₂ emissions when combined with an electric boiler.

Blades rotate at under 5 rpm, reducing wear and maintenance. Continuous, simple operation enables unmanned 24-hour running.

Lower Waste Volume, Disposal Costs, and CO₂ Emissions

Drying significantly reduces sludge weight and volume, cutting industrial waste fees and truck usage—critical as disposal and transport costs rise.

Fewer trucks also mean lower carbon emissions.

Supports Japan’s Resource Recovery Strategy

Dried sludge can be used to recover phosphorus and other valuable minerals—resources Japan heavily depends on.

KENKI DRYER enables the stable low-temperature drying necessary for recycling and resource recovery.

Trusted by Industry Leaders

KENKI DRYER is recognized for its uniform drying, durability, low manpower needs, simple installation, and low operating costs.

For sticky sludge, slurry, beverage lees, organic waste, or recycling materials, KENKI DRYER is the most reliable solution available today.

Comparison Table: Why Companies Choose KENKI DRYER

| Feature / Issue | Conventional Dryers | KENKI DRYER (11 Patents) |

|---|---|---|

| Handling sticky/sludge materials | Frequently clogs | Never clogs due to patented mechanism |

| Drying uniformity | Surface dries only | Core-to-surface uniform drying |

| Lump/crust formation | Causes uneven heating | Crushes lumps inside the dryer |

| Heat source efficiency | High fuel cost | High thermal efficiency, low steam use |

| CO₂ emissions | Often significant | Zero CO₂ when using electric boiler |

| Operation mode | Batch, labor-intensive | Continuous 24/7 unmanned operation |

| Maintenance frequency | High | Extremely low (≤5 rpm blade rotation) |

| Upcycling suitability | Often poor | Ideal for compost, fuel, recycling |

Frequently Asked Questions (FAQ)

Q: Can KENKI DRYER handle extremely sticky or adhesive sludge?

A: KENKI DRYER is specifically engineered for materials that clog other dryers. Its patented internal mechanism ensures smooth, clog-free drying.

Q: How does KENKI DRYER ensure uniform drying of lumpy sludge?

A: It crushes and reduces the size of sludge lumps inside the dryer, increasing heat penetration and ensuring that both the surface and the core dry evenly.

Q: Is low-temperature drying beneficial for upcycling?

A: Absolutely. Low-temperature steam drying preserves material components, making the dried output suitable for compost, soil conditioners, fuel, and recycling.

Q: How environmentally friendly is KENKI DRYER?

A: Very. It uses less steam, reduces CO₂ emissions, and can achieve zero greenhouse gas emissions when paired with an electric boiler.

Q: Can KENKI DRYER operate without manpower?

A: Yes. As a continuous dryer with simple operation and minimal maintenance, it can run 24/7 unmanned.

Q: Why is KENKI DRYER important for Japan’s mineral resource strategy?

A: Dried sludge can be used to extract phosphorus and recover valuable minerals—critical for reducing Japan’s reliance on imports.

Q: Which industries benefit most from KENKI DRYER?

A: Wastewater treatment facilities, food and beverage plants, recycling centers, sludge-processing companies, and any firm handling sticky organic waste.

If You Need a Dryer That Never Clogs — Choose KENKI DRYER

We are ready to propose the optimal model for your sludge, waste, or slurry processing needs.

KENKI DRYER: 11 Patents. Proven Performance. The Dryer That Others Cannot Match.

Videos / Drying Sticky, Adhesive, and High-Moisture Sludge

Revolutionize Your Sludge Drying Operations: The KENKI DRYER Solution

The Sticky Sludge Crisis: Why Traditional Dryers Fail Your Wastewater Treatment Plant

Wastewater treatment plants discharge sticky, adhesive sludge that causes traditional dryers to fail. Flocculants used in wastewater treatment cause sludge to clump together during the drying process. When lumps form, heat cannot penetrate the material’s core, leaving the interior wet while only the surface dries. This inefficiency leads to clogging inside the dryer, production shutdowns, frequent maintenance, and ultimately, failed operations. The rising industrial waste disposal costs and trucking challenges of 2024 compound these problems, forcing companies to transport heavier, inadequately dried sludge at premium rates. Your facility needs a breakthrough solution.

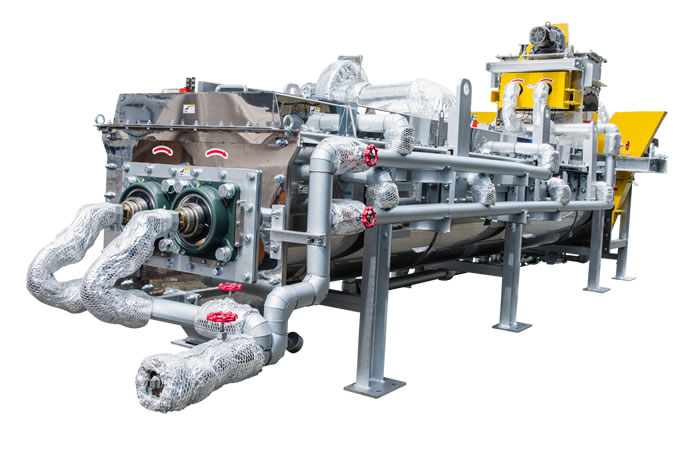

KENKI DRYER: 11 Patents for Adhesive Sludge Drying Innovation

KENKI DRYER is a revolutionary indirect steam dryer engineered specifically for sticky and adhesive materials that defeat conventional technology. With 11 patents granted across 8 countries (Japan, Taiwan, USA, France, Germany, UK, Switzerland, Canada), KENKI DRYER represents truly innovative sludge dryer technology. Unlike batch dryers, KENKI DRYER operates as a continuous system with uniquely designed blades rotating at just 5 rpm. This design crushes and reduces material size within the dryer chamber, eliminating lumps and ensuring uniform heat distribution. The result is complete, thorough drying of even the stickiest sludge without internal clogging or material adhesion problems.

Three Critical Problems Solved by KENKI DRYER’s Continuous Drying System

The low-temperature steam process solves three critical challenges facing facility managers. First, it prevents clogging and material buildup by continuously processing and sizing down sticky materials, allowing seamless discharge without operational interruptions. Second, it achieves complete drying to reduce weight and volume significantly, cutting transportation costs and disposal fees compared to traditional wastewater sludge dryers. Third, it preserves sludge composition through low-temperature indirect steam heating, enabling valuable upcycling applications as compost, soil conditioner, or fuel. This transforms a disposal liability into a profit-generating asset suitable for mineral extraction and sludge recycling initiatives.

Environmental Leadership Through Zero-Emission Sludge Drying Technology

KENKI DRYER delivers exceptional environmental and financial benefits that align with corporate decarbonization goals. High heat efficiency minimizes fuel consumption, and with an electric boiler installation, produces zero CO2 emissions during the drying process—supporting your facility’s environmental commitments. Reduced truck transportation volume through effective sludge dehydration lowers carbon emissions and waste management costs further. The low 5 rpm blade rotation means minimal equipment wear, resulting in easy maintenance, remarkably low operating costs, and 24-hour unmanned continuous operation requiring fewer personnel.

Why KENKI DRYER Outperforms Competing Sludge Drying Solutions

Companies installing KENKI DRYER report superior results: uniform drying quality, improved productivity, exceptional durability, and easy installation. Whether handling difficult wastewater treatment sludge, sticky slurry, beverage lees, or pursuing waste upcycling and organic waste recycling initiatives, KENKI DRYER delivers where standard industrial dryers fail. The 11 patents backing this technology demonstrate genuine innovation, engineering excellence, and proven reliability in the sludge drying industry.

Transform Your Sludge Drying Challenge Into Operational Excellence Today

Your facility deserves a high-moisture organic waste dryer that actually works. KENKI DRYER eliminates the frustration of clogging, material adhesion, and incomplete drying while reducing costs and environmental impact. Contact us today to discover how our patented continuous sludge drying system can optimize your wastewater treatment operations and support your facility’s sustainability objectives.

Test case / Drying Sticky, Adhesive, and High-Moisture Sludge

Test Results / Drying Sticky, Adhesive, and High-Moisture Sludge

- Material to be dry: Sticky, adhesive, and high-moisture organic sludge

- Purpose of drying: Upcycling, Industrial waste cost and amount

- Moisture content: 86.3%W.B. before drying, 12.7%W.B. after drying

- Requirements for dryer: To prevent clogging inside the dryer caused by the stickiness and adhesiveness. Automated continuous operation with no operator attended.

- Test result: OK

Organic sludge drying / Brochure

No matter how sticky, adhesive and viscous the material is, KENKI DRYER of International Patent can dry it without clogging inside of dryer and with stable operation that no operational trouble occurs because of its unique mechanism. For example, even materials stuck to the blades of one screw, blades of the other screw in the dryer’s body forcibly peels the materials off as they rotate. Since the blades rotate by peeling the material off each other, any sticky, adhesive and viscous material does not adhere to the blade, and the blades continue rotating, peeling, agitating and heating material without stopping while they carries material further. Also, since surface of blades are always renewed and kept clean, heat near the blades is not blocked and it is conducted directly into the materials.

You must be logged in to post a comment.