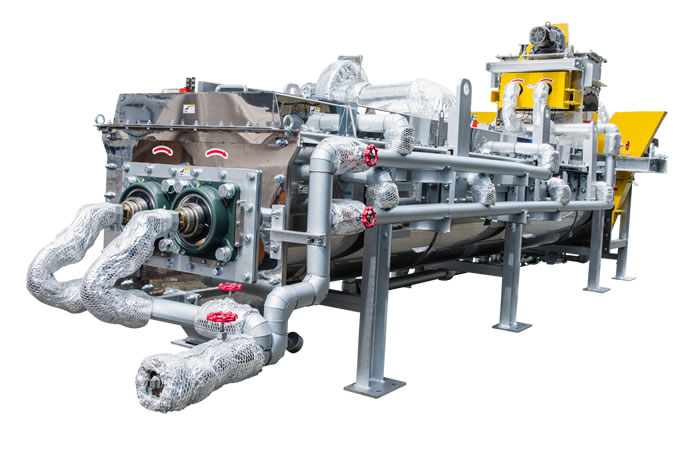

Dry the Impossible. Unlock Value from Lumped Materials. / KENKI DRYER / Raw materials dryer

Continuous, Low-Temperature, Clog-Free Drying for Sticky & Lumped Feedstocks

Solve Lumped Material Drying—Once and for All

Companies handling lumped, sticky, and adhesive materials face constant drying failures: clogging inside the dryer, uneven moisture, unstable discharge, and high operating costs. KENKI DRYER eliminates these problems.

Its patented internal mechanism gently breaks down lumps inside the dryer, increases effective surface area, and dries the core uniformly—even for materials others cannot handle.

Clog-Free Drying with Patented Technology

Lumped materials often become more adhesive during heating, causing blockage and shutdowns in conventional dryers. KENKI DRYER’s world-patented structure prevents internal clogging, enabling smooth, continuous discharge without manual intervention.

This means stable operation, no accumulation, and no unexpected stops—even with highly adhesive feedstocks.

Continuous, Low-Temperature Drying—24/7 Unmanned Operation

Unlike batch dryers, KENKI DRYER is a continuous low-temperature dryer.

It operates 24 hours a day without manpower, delivers consistent quality, and minimizes component degradation, preserving material value for recycling and upcycling applications.

Decarbonized Drying with Exceptional Energy Efficiency

KENKI DRYER is an indirect steam dryer with a structure entirely different from conventional steam dryers.

- No direct flame, no CO₂ emissions from the dryer

- High thermal efficiency → minimal steam consumption

- Can use existing surplus steam at no additional fuel cost

- Fully CO₂-free drying when paired with electric or hydrogen boilers

In contrast, direct-fired dryers emit CO₂, consume expensive fuel, and suffer rapid wear due to high temperatures.

Low Wear, Easy Maintenance, Proven Reliability

With an internal blade speed of below 5 RPM, mechanical stress is minimal.

- Virtually no post-startup troubles

- Low wear and long service life

- Simple, low-cost maintenance

This reliability enables true 24/7 unmanned operation and dramatically lowers total ownership cost.

Turn Waste into Resources—Profitably

Drying residual materials enables:

- Reduced raw material procurement costs

- Lower industrial waste volumes

- Reduced disposal and transport costs

- Lower CO₂ emissions from logistics

For resource-import-dependent economies, recycling minerals and valuable components from waste is not only environmentally essential—but strategically critical.

Key Benefits at a Glance

| Challenge | KENKI DRYER Solution |

|---|---|

| Lumped, sticky materials | Internal size-reduction & uniform core drying |

| Clogging & shutdowns | Patented clog-free structure |

| Uneven drying | Low-temperature, continuous operation |

| High fuel & CO₂ emissions | Steam drying, surplus steam use, zero CO₂ option |

| High maintenance costs | <5 RPM rotation, low wear |

| Labor-intensive operation | 24/7 unmanned continuous drying |

| Limited reuse of dried output | Minimal component change, ideal for upcycling |

Frequently Asked Questions

Q: Can KENKI DRYER really dry large lumps?

A: Yes. Lumps are partially broken down inside the dryer, increasing surface area and enabling uniform internal drying.

Q: Will sticky materials clog the dryer?

A: No. The patented internal mechanism prevents clogging, even with highly adhesive materials.

Q: Does drying change material properties?

A: Drying is performed at low temperature, so material composition remains stable, supporting recycling and reuse.

Q: Is CO₂-free drying possible?

A: Yes. Using surplus steam, electric boilers, or hydrogen boilers, drying can be achieved with zero CO₂ emissions.

Q: Is continuous unmanned operation safe?

A: Absolutely. The system is designed for stable, trouble-free 24-hour operation with minimal maintenance.

The Dryer Others Cannot Build

KENKI DRYER holds 11 patented technologies across 8 countries and specializes in drying materials no other dryer can handle—sticky, adhesive, high-moisture, and lumped feedstocks.

It is trusted worldwide for raw material drying, sludge drying, slurry drying, beverage residue drying, digestate drying, recycling, and upcycling applications.

If you are struggling with materials that cannot be dried, KENKI DRYER is the answer.

Contact us anytime—we will propose the optimal drying solution tailored to your process.

Videos / Raw material residue Drying

A Proven Solution for Lumped & Sticky Material Drying

KENKI DRYER solves the toughest challenge in industrial drying: lumped, sticky, and adhesive materials. Even materials that normally clog dryers are gently reduced in size inside the machine, increasing surface area and enabling uniform internal drying without blockage.

Thanks to its world-patented internal mechanism, KENKI DRYER never clogs. Sticky materials that would normally accumulate and stop operation are smoothly dried and continuously discharged, ensuring stable, stress-free operation.

KENKI DRYER is a continuous, low-temperature dryer, not a batch system. It allows 24/7 unmanned operation, minimizes changes to material composition, and produces dried output ideal for recycling and upcycling applications.

Unlike direct-fired dryers, KENKI DRYER uses high-efficiency indirect steam heating. Steam consumption is low, existing or surplus steam can be reused, and no CO₂ is emitted from the dryer during operation. When combined with electric or hydrogen boilers, drying is completely carbon-free.

With blade rotation below 5 RPM, wear is minimal. There are virtually no post-startup troubles, maintenance is simple, and running costs remain low over long-term use.

Drying residual materials reduces waste volume, disposal costs, transport emissions, and raw material purchases—while supporting resource recovery, decarbonization, and sustainable growth.

Holding 11 patents across 8 countries, KENKI DRYER is trusted worldwide for sludge, slurry, organic waste, beverage residues, digestate, and recycling applications.

If your material is considered “undryable,” KENKI DRYER is the solution others cannot offer.

Test case / Raw material residue Drying

Test Results / Raw material residue Drying

- Material to be dry: Raw material residue

- Purpose of drying: Recycling, Industrial waste cost and amount

- Moisture content: 46.7%W.B. before drying, 1.4%W.B. after drying

- Requirement for Dryer: Drying with minimal component changes for use as recycled material. Must not clog inside the dryer due to tendency to adhere. Capable of 24-hour unattended operation. Recoup equipment costs within a short period.

- Test result: OK

Slurry drying / Brochure

KENKI DRYER which uses International Patented Technology can dry sticky, adhesive and viscous material containing high moisture contents and liquid material that no other company can deal with. It can dry without clogging inside of the dryer and with safe operation which meets no operational trouble. Organic wastes with high moisture contents such as coffee grounds,used tea leaves, soy pulps, livestock excretions, food residues, vegetables, fruits scraps, residues of processed marine product, etc. can be dried smoothly and each of these materials are discharged as valuable product with stable quality after drying.

You must be logged in to post a comment.