KENKI DRYER: Innovative Low-Temperature Drying Solution for Sticky Organic Waste

Transform Adhesive Waste into Valuable Resources While Reducing Carbon Emissions

Introduction

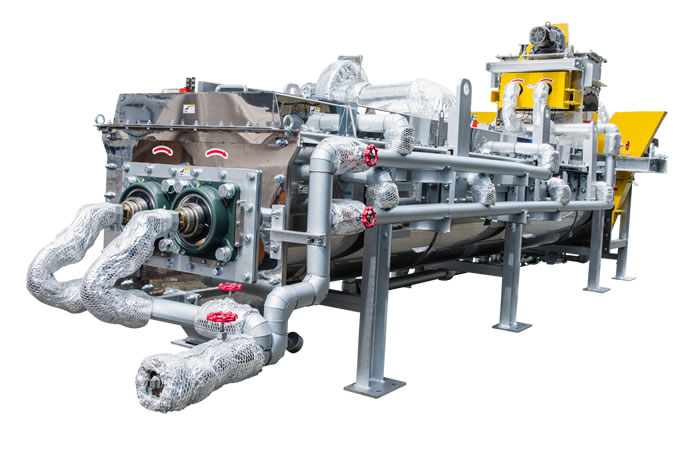

Managing sticky and adhesive organic waste has always been challenging for manufacturers. Traditional dryers often struggle with clogging and inefficient processing. KENKI DRYER revolutionizes this process with patented technology that smoothly dries even the most difficult sticky organic waste materials. Our solution combines sustainability, cost-efficiency, and reliability—making it the ideal choice for modern waste management and upcycling.

Key Benefits of KENKI DRYER

KENKI DRYER’s world-patented mechanism enables efficient drying of high moisture-content organic waste without clogging. By utilizing steam indirect heating at low temperatures, the dryer preserves material composition, allowing for superior upcycling and resource recovery. Unlike direct-fire dryers, our system produces zero CO₂ emissions during operation, supports 24/7 unattended operation, and requires minimal maintenance.

The low-speed rotating blade (below 5 RPM) significantly reduces component wear, lowering operational and maintenance costs. Whether using existing boiler steam, surplus steam, or renewable energy sources (electric or hydrogen boilers), KENKI DRYER delivers eco-friendly, cost-effective performance.

Why Choose KENKI DRYER?

| Feature | Benefit |

|---|---|

| Patented Technology | 8 countries, 11 patents—globally recognized innovation |

| Low-Temperature Processing | Preserves material quality for effective upcycling and resource recovery |

| Continuous Operation | 24/7 unattended drying—no labor required |

| Steam-Powered Efficiency | Uses existing boiler steam or surplus capacity; zero fuel costs possible |

| Zero Emissions | Decarbonized drying with zero operational CO₂ |

| Minimal Maintenance | Low-speed operation (≤5 RPM) reduces wear and maintenance expenses |

| Trouble-Free Performance | Proven reliability with zero post-installation issues |

Applications & Upcycling Opportunities

Dried organic waste can be transformed into valuable resources:

- Fertilizers & Soil Amendments – Direct agricultural application

- Animal Feed – For livestock including cattle and poultry

- Bioplastics & Biodegradable Materials – Plant-based plastic alternatives

- Biochar & Biocoke – High-value fuel and metallurgical reducing agents (in partnership with our Biogreen pyrolysis system)

Frequently Asked Questions (Q&A)

Q: Will sticky waste clog the dryer?

A: No. KENKI DRYER’s unique patent-protected design prevents clogging even with highly adhesive waste, thanks to its specialized internal mechanism.

Q: What happens to the dried waste?

A: Depending on composition, dried waste can be used as fertilizer, animal feed, biofuel, or converted into biochar—adding value while reducing landfill waste.

Q: Can KENKI DRYER operate unattended?

A: Yes. As a continuous-feed system, it requires no manual intervention and operates reliably 24/7.

Q: What are the operating costs?

A: KENKI DRYER uses existing steam from your facility. If surplus steam is available, operational costs are minimal. Combined with low maintenance requirements, total cost of ownership is significantly reduced.

Q: How does this support carbon reduction goals?

A: By reducing waste weight, fewer transport trips are needed (lower CO₂). Plus, zero operational emissions and potential use of renewable energy sources make KENKI DRYER a true decarbonization solution.

Global Reliability

Patents secured in: Japan, Taiwan, USA, France, Germany, UK, Switzerland, and Canada (8 countries, 11 patents)

KENKI DRYER is trusted by leading manufacturers worldwide for trouble-free performance, high productivity, and durability.

Videos / Low-temperature drying of highly sticky and adhesive organic waste

Low-Temperature, Clog-Free Drying for Highly Adhesive Organic Waste

Highly adhesive, high-moisture organic waste is extremely difficult to dry, often causing clogging, unstable operation, odors, and rising disposal costs when handled by conventional dryers. KENKI DRYER solves these challenges with a globally patented, clog-free mechanism that enables smooth, continuous low-temperature drying even for the stickiest organic waste. By rapidly reducing moisture, it suppresses bacterial and mold activity, preventing decay and foul odors while improving plant hygiene. Weight and volume reduction significantly lowers disposal and transportation costs and cuts CO₂ emissions, directly supporting decarbonization goals. Using indirect low-temperature steam drying, KENKI DRYER preserves material components, making the dried product ideal for upcycling into fertilizer, compost, soil conditioners, animal feed, biomass fuel, biochar, biocoke, or bioplastic feedstock. With 11 patents across 8 countries, high thermal efficiency, zero CO₂ emissions during drying when using surplus steam or electric and hydrogen boilers, ultra-low rotation speed below 5 RPM, minimal maintenance, and reliable 24-hour unmanned continuous operation, KENKI DRYER is the proven solution for companies seeking stable drying, low running costs, and maximum value creation from organic waste.

Test case / Low-temperature drying of highly sticky and adhesive organic waste

Test Results / Low-temperature drying of highly sticky and adhesive organic waste

- Material to be dry: Highly sticky and adhesive Organic Waste

- Purpose of drying: Upcycling, Industrial waste cost and amount

- Moisture content: 83.2%W.B. before drying, 12.8%W.B. after drying

- Requirements for dryer: To prevent clogging inside the dryer caused by the stickiness and adhesiveness. Automated continuous operation with no operator attended.

- Test result: OK

Organic waste drying / Brochure

No matter how sticky, adhesive and viscous the material is, KENKI DRYER of International Patent can dry it without clogging inside of dryer and with stable operation that no operational trouble occurs because of its unique mechanism. For example, even materials stuck to the blades of one screw, blades of the other screw in the dryer’s body forcibly peels the materials off as they rotate. Since the blades rotate by peeling the material off each other, any sticky, adhesive and viscous material does not adhere to the blade, and the blades continue rotating, peeling, agitating and heating material without stopping while they carries material further. Also, since surface of blades are always renewed and kept clean, heat near the blades is not blocked and it is conducted directly into the materials.

You must be logged in to post a comment.