Sludge Drying Without Clogging / The Ultimate Solution for Sticky, High-Moisture Sludge — KENKI DRYER

Solve the “Undryable” Sludge Problem Once and for All

Drying sticky sludge is one of the toughest challenges in industrial drying.

Drying sludge with strong adhesive and sticky properties is extremely difficult using conventional dryers. Sludge often adheres to internal surfaces, causes clogging, and cannot be discharged smoothly, resulting in unstable operation, higher maintenance costs, and interrupted production.

KENKI DRYER eliminates clogging and enables stable continuous drying.

Even highly adhesive, viscous, and high-moisture organic sludge can be dried smoothly and continuously without clogging, completely solving problems that conventional dryers cannot overcome.

Wastewater treatment sludge is especially prone to clogging in conventional dryers.

In many dryer types, sludge discharged from wastewater treatment plants accumulates inside the machine during drying, leading to blockages and shutdowns. KENKI DRYER uses a unique, internationally patented mechanism that prevents internal clogging and ensures smooth material flow and stable discharge.

KENKI DRYER breaks sludge lumps and dries them thoroughly from the inside.

Sludge treated with flocculants tends to form large lumps during drying. Conventional dryers dry only the surface, leaving the inside wet. KENKI DRYER gently reduces agglomerates inside the dryer, increases effective surface area, and allows heat to penetrate deep into the material for uniform drying.

Low-temperature steam drying preserves material quality for upcycling.

KENKI DRYER is an indirect, low-temperature steam dryer that minimizes changes in material composition. This allows dried sludge to be reused as compost, soil conditioners, solid fuel, or feedstock for carbonization into biochar or bio-coke.

Sludge drying reduces disposal costs and supports decarbonization.

By significantly reducing sludge weight and volume, disposal costs are lowered, truck transportation is reduced, and CO₂ emissions from logistics decrease, contributing directly to environmental protection and decarbonization.

KENKI DRYER is a truly unique steam dryer with superior energy efficiency.

Unlike conventional steam dryers, KENKI DRYER generates no combustion gas and emits no CO₂ from the dryer itself. Its high thermal efficiency reduces steam consumption, and surplus steam can be reused, enabling very low energy-cost drying. When combined with electric or hydrogen boilers, fully zero-CO₂ drying is possible.

Low-speed operation ensures reliability and easy maintenance.

Operating at an ultra-low rotation speed of less than 5 RPM, KENKI DRYER experiences minimal wear, low maintenance costs, and exceptional reliability. As a continuous dryer rather than a batch system, it supports stable 24-hour unmanned operation.

Sludge upcycling is becoming a global priority.

Worldwide demand for sludge recycling is increasing due to resource recovery needs, reduced dependence on imported materials, and national decarbonization strategies. Dried sludge can be reused as an alternative fuel to wood biomass or carbonized into biochar or bio-coke for steelmaking and foundry industries, expanding its value as a sustainable resource.

Comparison Table: Why Companies Choose KENKI DRYER

| Challenge with Conventional Dryers | KENKI DRYER Solution |

|---|---|

| Severe clogging with sticky sludge | Unique patented anti-clog mechanism |

| Lumps remain wet inside | Internal size reduction for deep drying |

| High energy and fuel costs | High thermal efficiency, low steam use |

| CO₂ emissions from burners | CO₂-free indirect steam drying |

| Frequent maintenance | Ultra-low rotation, minimal wear |

| Batch operation complexity | Continuous, 24/7 unmanned operation |

Frequently Asked Questions (FAQ)

Q: Can KENKI DRYER really dry extremely sticky sludge?

A: Yes. KENKI DRYER is specifically designed for sticky, adhesive, and high-moisture sludge that other dryers cannot handle—without clogging.

Q: Does drying change sludge composition?

A: No. Low-temperature indirect steam drying minimizes component degradation, making the dried product ideal for upcycling.

Q: Is CO₂ generated during drying?

A: No CO₂ is emitted from the dryer itself. When surplus steam, electric boilers, or hydrogen boilers are used, the process can be completely carbon-free.

Q: Is continuous operation possible?

A: Yes. KENKI DRYER is a continuous system capable of stable 24-hour unmanned operation.

Turn Sludge from a Cost into a Resource

KENKI DRYER holds 11 patents across 8 countries and is trusted worldwide for drying materials that no other dryer can handle.

If your company struggles with sticky sludge, high disposal costs, or unstable drying operations, KENKI DRYER is the proven solution.

📩 Contact us today for a tailored drying solution and test evaluation.

Videos / The Sludge Dryer That Others Cannot Handle

KENKI DRYER: The Ultimate Solution for Difficult Sludge Drying

Eliminate Equipment Clogging and Reduce Disposal Costs with Patented Indirect Steam Technology

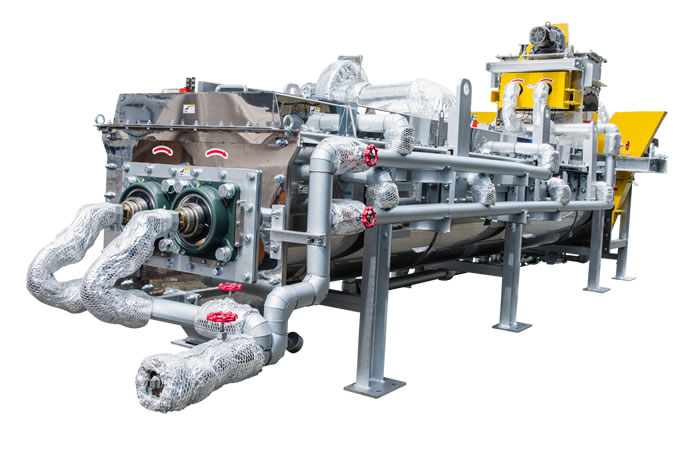

Wastewater treatment facilities face a persistent challenge: drying highly adhesive and sticky sludge. Traditional dryers often fail due to clogging and incomplete drying. KENKI DRYER is the patented solution designed for difficult sludge drying applications that other equipment cannot handle. With 11 patents across 8 countries, KENKI DRYER employs proprietary indirect steam heating technology to dry even the most problematic sludge efficiently and sustainably. Wastewater sludge contains coagulants that cause adhesion and blockages in conventional dryers. Sludge forms hard clumps where only the exterior dries while interiors remain wet and unsuitable for reuse. With 80-95% water content, standard dryers fail catastrophically. KENKI DRYER’s patented design features a unique internal structure that prevents material adhesion and clogging. The system gently breaks down lumps and reduces particle size, allowing heat to penetrate completely through the material. Operating below 100°C with steam heating, KENKI DRYER preserves material composition while eliminating CO₂ emissions and reducing fuel costs significantly. The internal blade rotates at just 5 RPM, ensuring minimal wear, simple maintenance, and zero post-installation issues. The continuous-feed system operates unmanned 24/7.

Environmental and cost benefits are immediate and substantial. Using existing or renewable steam sources, KENKI DRYER eliminates direct CO₂ emissions during operations. Dried sludge is 70-80% lighter, reducing transport trucks and disposal costs by 50-70%. Many facilities achieve zero fuel costs by utilizing otherwise-wasted steam. Repair expenses reduce by 60-80% compared to conventional dryers. Low-temperature processing preserves sludge composition for valuable upcycling as biofuel, compost, biochar, and nutrient recovery. KENKI DRYER is ideal for municipal and industrial wastewater treatment, food processing, brewery operations, and biosolids processing. If you’re experiencing frequent clogging, incomplete drying, high maintenance costs, or expensive disposal, contact us for a consultation to assess your specific needs.

Why Choose KENKI DRYER?

11 Patents in 8 Countries represent proven, award-winning technology. KENKI DRYER handles sticky, adhesive sludge that standard dryers reject—what others cannot do. The unique patented design prevents equipment failure through zero internal clogging. The system breaks lumps for complete moisture removal, ensuring thorough interior drying. Ultra-low operating costs make it possible to run on excess steam, potentially achieving zero fuel cost operations. The 5 RPM blade reduces wear and repair needs, with minimal maintenance requirements. The continuous-feed system requires no operator, enabling 24/7 unmanned operation. KENKI DRYER delivers environmental excellence with zero CO₂ emissions when using renewable energy sources. The low-temperature process preserves sludge composition for valuable upcycling and asset recovery. The track record of zero post-installation issues makes KENKI DRYER highly rated by users worldwide.

Test case / Clog-Free Sludge Drying for High-Moisture Waste

Test Results / Turn Sticky Sludge into a Valuable Resource

- Material to be dry: Sticky, adhesive, and high-moisture organic sludge

- Purpose of drying: Industrial waste cost and amount

- Moisture content: 84.8%W.B. before drying, 16.4%W.B. after drying

- Requirements for dryer: To prevent clogging inside the dryer caused by the stickiness and adhesiveness. Automated continuous operation with no operator attended.

- Test result: OK

Organic sludge drying / Brochure

No matter how sticky, adhesive and viscous the material is, KENKI DRYER of International Patent can dry it without clogging inside of dryer and with stable operation that no operational trouble occurs because of its unique mechanism. For example, even materials stuck to the blades of one screw, blades of the other screw in the dryer’s body forcibly peels the materials off as they rotate. Since the blades rotate by peeling the material off each other, any sticky, adhesive and viscous material does not adhere to the blade, and the blades continue rotating, peeling, agitating and heating material without stopping while they carries material further. Also, since surface of blades are always renewed and kept clean, heat near the blades is not blocked and it is conducted directly into the materials.

You must be logged in to post a comment.