Clog-Free Low-Temperature Drying of Liquid Raw Material Slurry / KENKI DRYER / Liquid dryer, Slurry dryer

The proven solution for sticky and adhesive slurry drying

Low-Temperature Drying Solution for Sticky Liquid Raw Material Slurry

Drying liquid raw material slurry with strong stickiness and adhesiveness is one of the most challenging processes in manufacturing.

Many conventional dryers suffer from clogging inside the dryer, unstable discharge, uneven drying, and frequent operational troubles when handling high-moisture slurry materials.

KENKI DRYER was specifically developed to solve these fundamental problems.

Even extremely sticky and adhesive liquid slurry can be dried smoothly and continuously without clogging, ensuring stable and reliable operation.

Stable Drying Without Clogging

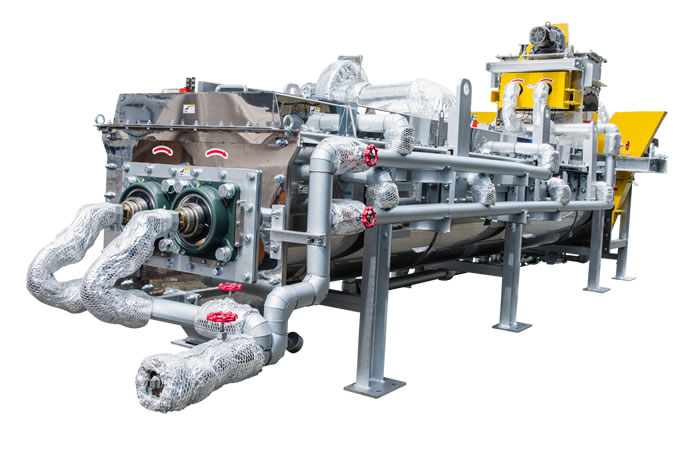

KENKI DRYER features a patented internal structure that prevents material buildup inside the dryer.

Unlike conventional dryers where sticky slurry adheres to internal surfaces and causes blockages, KENKI DRYER allows the material to move continuously and discharge smoothly.

As a result, drying operations remain stable even when processing difficult, high-moisture slurry materials that cannot be handled by other drying technologies.

Low-Temperature Drying with Minimal Change in Material Composition

KENKI DRYER uses saturated steam as its only heat source and operates at low drying temperatures.

This low-temperature drying process minimizes thermal damage and prevents changes in material composition after drying.

By combining indirect conductive heat transfer with controlled hot air, heat penetrates evenly throughout the material.This ensures uniform drying without surface hardening or uneven moisture distribution, making t

This ensures uniform drying without surface hardening or uneven moisture distribution, making the dried product suitable for high-quality product manufacturing.

Continuous, Unmanned, 24/7 Operation

KENKI DRYER is a continuous drying system, not a batch-type dryer.

It does not require operators to load or unload material manually, enabling fully automated and unmanned operation.

With stable performance and simple operation control, KENKI DRYER can run continuously for 24 hours a day, significantly reducing labor requirements and operational stress compared to tray or shelf dryers.

High Durability and Low Maintenance Cost

The paddle rotation speed inside KENKI DRYER is less than 5 RPM.

This extremely slow rotation minimizes mechanical wear, resulting in long equipment life and very low maintenance costs.

After installation, operational troubles are rare, and routine maintenance is simple and inexpensive, contributing to a low total cost of ownership.

Decarbonized and Energy-Efficient Drying

KENKI DRYER emits no CO₂ from the drying process itself.

It can utilize existing steam systems or surplus steam, allowing manufacturers to reduce fuel consumption and operating costs.

When combined with electric or hydrogen boilers, KENKI DRYER enables completely carbon-free drying, supporting decarbonization and environmental sustainability goals.

A Unique Drying Technology Protected by Global Patents

KENKI DRYER is protected by 11 patents in 8 countries, including Japan, the United States, Europe, and Asia.

Although it is classified as an indirect steam dryer, its internal structure and drying mechanism are completely different from conventional steam dryers.

This patented technology allows KENKI DRYER to dry materials that no other dryer can handle, including liquid slurry, sticky raw materials, sludge, organic waste, and upcycling feedstock.

Comparison Table: KENKI DRYER vs Conventional Dryers

| Item | KENKI DRYER | Conventional Dryers |

|---|---|---|

| Sticky slurry handling | Excellent (clog-free) | Poor (frequent clogging) |

| Drying temperature | Low temperature | High temperature |

| Composition change | Minimal | Likely |

| Drying uniformity | Highly uniform | Uneven |

| Operation mode | Continuous | Often batch |

| Labor requirement | None (unmanned) | High |

| Maintenance | Low | High |

| CO₂ emissions | None from dryer | High (direct firing) |

Frequently Asked Questions

Q: Can KENKI DRYER really dry highly sticky liquid slurry?

A: Yes. Its patented internal structure prevents clogging, even with extremely sticky and adhesive slurry.

Q: Does low-temperature drying affect productivity?

A: Minimal. Low-temperature indirect drying preserves material properties, making it suitable for product manufacturing.

Q: Will the material composition change after drying?

A: Minimal. Low-temperature indirect drying preserves material properties, making it suitable for product manufacturing.

Q: Is continuous unmanned operation possible?

A: Yes. KENKI DRYER is designed for stable 24-hour continuous unmanned operation.

Q: Is it suitable for decarbonization strategies?

A: Absolutely. It emits no CO₂ during drying and can utilize surplus steam or carbon-free energy sources.

Conclusion

KENKI DRYER is a breakthrough low-temperature drying solution for liquid raw material slurry.

It delivers clog-free drying, minimal composition change, uniform product quality, unmanned continuous operation, and excellent energy efficiency.

For manufacturers facing challenges in slurry drying and sticky material processing, KENKI DRYER offers a reliable, proven, and future-ready solution.

Videos / Solving Sticky Slurry Drying Challenges with KENKI DRYER

The Only Dryer That Can Handle Highly Sticky Liquid Slurry

Drying liquid raw material slurry with strong stickiness and adhesiveness is one of the most difficult challenges in industrial drying.

Conventional dryers often suffer from clogging, unstable discharge, uneven drying, and product degradation caused by high temperatures.

KENKI DRYER was developed to solve these issues fundamentally.

Even highly sticky, adhesive, and high-moisture slurry can be dried smoothly and continuously without clogging, ensuring stable operation.

KENKI DRYER uses saturated steam as the sole heat source and performs drying at low temperatures.

By combining indirect conductive heat transfer and controlled hot air, the material is dried uniformly from the inside, preventing surface hardening and drying unevenness.

As a result, material composition changes are minimized, making it ideal for product manufacturing and raw material drying.

The system operates as a continuous dryer, not a batch process.

It requires no manual operation, enables 24/7 unmanned operation, and dramatically reduces labor and operational burden compared to tray or shelf dryers.

In addition, KENKI DRYER is an indirect steam dryer with a completely unique structure, protected by 11 patents in 8 countries.

The paddle rotation speed is below 5 RPM, resulting in minimal wear, high durability, and extremely low maintenance costs.

From an environmental perspective, KENKI DRYER supports decarbonized drying.

No CO₂ is emitted from the dryer itself.

Existing steam systems or surplus steam can be reused, significantly reducing energy costs.

With electric or hydrogen boilers, zero greenhouse gas emissions during drying can be achieved.

Test case / Low-Temperature Slurry Drying Without Composition Change

Test Results / Advanced Low-Temperature Drying Technology for Liquid Slurry Materials

- Material to be dry: Liquid raw material slurry

- Purpose of drying: Product Manufacturing

- Moisture content: 97.9%W.B. before drying, 3.2%W.B. after drying

- Requirement for Dryer: To prevent clogging inside the dryer caused by the stickiness and adhesiveness. Low-temperature drying with minimal component changes. Automated continuous operation with no operator attended. Machine cost can be recovered in short term.

- Test result: OK

Slurry drying / Brochure

KENKI DRYER which uses International Patented Technology can dry sticky, adhesive and viscous material containing high moisture contents and liquid material that no other company can deal with. It can dry without clogging inside of the dryer and with safe operation which meets no operational trouble. Organic wastes with high moisture contents such as coffee grounds,used tea leaves, soy pulps, livestock excretions, food residues, vegetables, fruits scraps, residues of processed marine product, etc. can be dried smoothly and each of these materials are discharged as valuable product with stable quality after drying.

You must be logged in to post a comment.