Advanced Low-Temperature Drying for Lumpy and Sticky Sludge / KENKI DRYER / Sludge dryer, Upcycling dryer

Low-Temperature Upcycling Drying for Lumpy Sludge with KENKI DRYER

The Challenge of Drying Lumpy Sludge

After mechanical dewatering, sludge often becomes lumpy regardless of whether it is organic or inorganic. In wastewater treatment plants, the use of coagulants further increases adhesion, causing sludge to agglomerate during drying. These lumpy materials are extremely difficult to process with conventional dryers because heat cannot penetrate into the core of the lumps. As a result, surface-only drying, clogging inside the dryer, unstable operation, and frequent shutdowns are common challenges faced by many facilities.

Why Conventional Dryers Fail with Lumpy Materials

Most conventional sludge dryers are not designed to handle strong adhesion and lump formation. Sticky sludge adheres to internal surfaces, blocks material flow, and causes severe clogging. Even when the surface appears dry, the interior often remains wet, making consistent and complete drying impossible. These limitations prevent stable operation and significantly reduce productivity.

How KENKI DRYER Enables Uniform Internal Drying

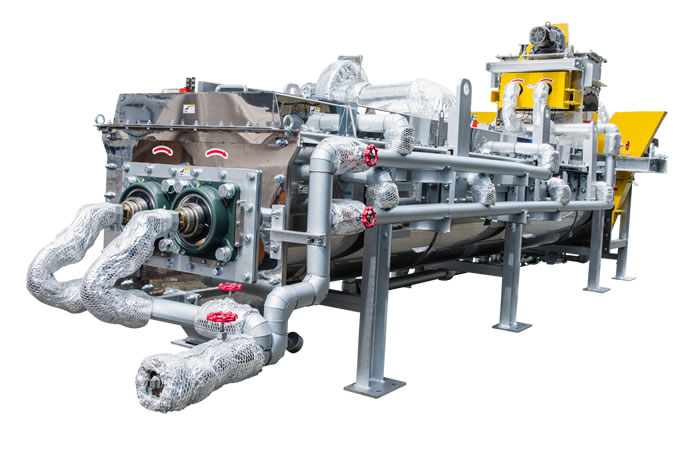

KENKI DRYER is a patented low-temperature sludge dryer specifically developed to solve these problems and enable stable upcycled sludge drying. Its unique internal mechanism gently disintegrates lumpy sludge inside the dryer, increasing the effective surface area during operation. This allows heat to penetrate deep into the material, enabling uniform internal drying without clogging, even for high-moisture and highly adhesive sludge.

Reliable Drying of Sludge Containing Coagulants

Sludge discharged from wastewater treatment plants is particularly difficult to dry because coagulants promote lump formation during heating. In many drying systems, this results in dried surfaces with wet cores. KENKI DRYER overcomes this issue by ensuring controlled internal breakdown of sludge lumps, allowing sufficient heat transfer and complete internal drying. As a result, even strongly adhesive and sticky dewatered sludge can be dried smoothly and reliably.

Cost Reduction and Decarbonization Benefits

Drying sludge significantly reduces its weight and volume, leading to lower industrial waste disposal costs. At the same time, fewer truck transports are required, which directly reduces CO₂ emissions. As logistics costs and fuel prices continue to rise, sludge drying has become an essential measure for both cost reduction and decarbonization.

Upcycled Sludge Drying and Resource Recovery

KENKI DRYER uses low-temperature indirect steam drying, which minimizes changes in chemical composition and preserves the value of dried sludge. This makes the dried material suitable for recycling and upcycling applications such as fuel, soil conditioners, compost materials, and feedstock for biochar and biocoke production. Recycling minerals contained in sludge, including phosphorus and other valuable resources, is increasingly important for environmental protection and resource security.

Low-Carbon Drying with High Energy Efficiency

Unlike direct-fired dryers that emit CO₂ and consume large amounts of fuel, KENKI DRYER achieves high thermal efficiency with minimal steam consumption and emits no CO₂ during the drying process itself. Existing steam systems or surplus steam can be utilized, and when combined with electric or hydrogen-fueled boilers, the process enables zero-emission sludge drying.

Continuous Operation with Low Maintenance

KENKI DRYER operates continuously rather than in batch mode, making operation simple and stable. The internal paddles rotate at less than 5 RPM, resulting in low wear and minimal maintenance requirements. This design enables reliable 24-hour unattended operation with low running costs and long equipment life.

Comparison Table

| Item | KENKI DRYER | Conventional Sludge Dryers |

|---|---|---|

| Handling of lumpy sludge | Uniform internal drying | Surface drying only |

| Clogging risk | No clogging | Frequent clogging |

| Drying method | Low-temperature, indirect steam | High-temperature, direct-fired |

| CO₂ emissions during drying | None | High |

| Operation | Continuous, stable | Often batch-based |

| Maintenance | Low, slow rotation | High due to wear |

| Suitability for upcycling | Excellent | Limited |

Frequently Asked Questions (FAQ)

Q: Can KENKI DRYER really dry large, lumpy sludge?

A: Yes. Lumps are gently broken down inside the dryer, allowing heat to penetrate fully and achieve uniform internal drying.

Q: Is sludge containing coagulants a problem?

A: No. Even sludge with strong adhesion caused by coagulants can be dried smoothly without clogging.

Q: What can the dried sludge be used for?

A: It can be reused as fuel, soil conditioner, compost material, or as feedstock for biochar and biocoke production.

Q: Is operation and maintenance complicated?

A: No. The low-speed, continuous design enables simple operation, low maintenance, and 24-hour unattended running.

Summary, A Proven Solution for Upcycled Sludge Drying

By enabling stable drying of lumpy and sticky sludge while preserving material value, KENKI DRYER transforms sludge from a disposal burden into a valuable resource. With patented technology, low-temperature drying, continuous operation, and low-carbon performance, KENKI DRYER provides a proven and practical solution for upcycled sludge drying, cost reduction, resource recovery, and decarbonization.

Videos / The Ultimate Solution for Lumpy Sludge Drying

No More Clogging in Lumpy Sludge Drying

After mechanical dewatering, sludge often becomes lumpy regardless of whether it is organic or inorganic. In wastewater treatment plants, the use of coagulants further increases adhesion, causing sludge to agglomerate during drying. These lumpy materials are extremely difficult to dry with conventional dryers because heat cannot penetrate into the core of the lumps. As a result, surface-only drying, clogging inside the dryer, unstable operation, and frequent shutdowns are common problems faced by many facilities.

KENKI DRYER is specifically engineered to overcome these challenges. Even when the feed material consists of lumpy sludge with strong adhesion and high moisture content, its patented internal mechanism gently disintegrates the lumps inside the dryer. By increasing the effective surface area during drying, heat is transferred efficiently into the interior of the sludge, enabling uniform drying from the surface to the core without clogging.

Sludge discharged from wastewater treatment plants is particularly challenging due to the influence of coagulants, which promote agglomeration during drying. In many conventional drying systems, this results in dried surfaces while the interior remains wet. With KENKI DRYER, even if sludge becomes lumpy during processing, controlled internal breakdown ensures sufficient heat transfer, achieving complete internal drying. Highly adhesive and sticky dewatered sludge can therefore be dried smoothly under continuous operation.

Drying sludge significantly reduces its weight and volume, leading to lower industrial waste disposal costs. At the same time, fewer truck transports are required, directly reducing CO₂ emissions. As logistics costs and fuel prices continue to rise, sludge drying has become an effective measure for both cost reduction and environmental protection, contributing to decarbonization initiatives.

Japan relies heavily on imported mineral resources, including rare metals and phosphorus. Recycling and reusing minerals contained in sludge is increasingly recognized as an important strategy for resource security and environmental protection. Phosphorus recovery from sewage sludge is already being promoted as a national project, and demand for sludge recycling and upcycling is steadily increasing.

KENKI DRYER employs low-temperature indirect drying using steam as the heat source. This gentle drying method minimizes changes in chemical composition, allowing dried sludge to retain its value for recycling and upcycling. The dried material can be reused as fuel, soil conditioner, compost material, or as feedstock for carbonization processes such as biochar and biocoke production.

Unlike direct-fired dryers that emit CO₂ and consume large amounts of fuel, KENKI DRYER achieves high thermal efficiency with minimal steam consumption. Existing steam systems or surplus steam can be utilized, significantly reducing operating costs. During the drying process, no CO₂ is emitted from the dryer itself, enabling low-carbon sludge drying. When combined with electric or hydrogen-fueled boilers, the process can operate with zero greenhouse gas emissions.

KENKI DRYER is a continuous dryer rather than a batch-type system, making operation simple and stable. The internal paddles rotate at less than 5 RPM, minimizing wear and reducing maintenance requirements. This design enables reliable 24-hour unattended operation with low running costs and minimal downtime.

Test case / Solving the Toughest Lumpy Sludge Drying Challenges

Test Results / Low-Temperature Upcycling Drying for Lumpy Sludge with KENKI DRYER

- Material to be dry: Lumpy organic sludge

- Purpose of drying: Upcycling, Industrial waste cost and amount

- Moisture content: 76.8%W.B. before drying, 7.2%W.B. after drying

- Requirements for dryer: To prevent clogging inside the dryer caused by the stickiness and adhesiveness. Automated continuous operation with no operator attended.

- Test result: OK

Organic sludge drying / Brochure

No matter how sticky, adhesive and viscous the material is, KENKI DRYER of International Patent can dry it without clogging inside of dryer and with stable operation that no operational trouble occurs because of its unique mechanism. For example, even materials stuck to the blades of one screw, blades of the other screw in the dryer’s body forcibly peels the materials off as they rotate. Since the blades rotate by peeling the material off each other, any sticky, adhesive and viscous material does not adhere to the blade, and the blades continue rotating, peeling, agitating and heating material without stopping while they carries material further. Also, since surface of blades are always renewed and kept clean, heat near the blades is not blocked and it is conducted directly into the materials.

You must be logged in to post a comment.